Whether your laundry project involves a new building design, renovation, expansion or simply purchasing a new piece of equipment, the plant layout will need to be reviewed to keep the facility working at its optimum speed for the foreseeable future.

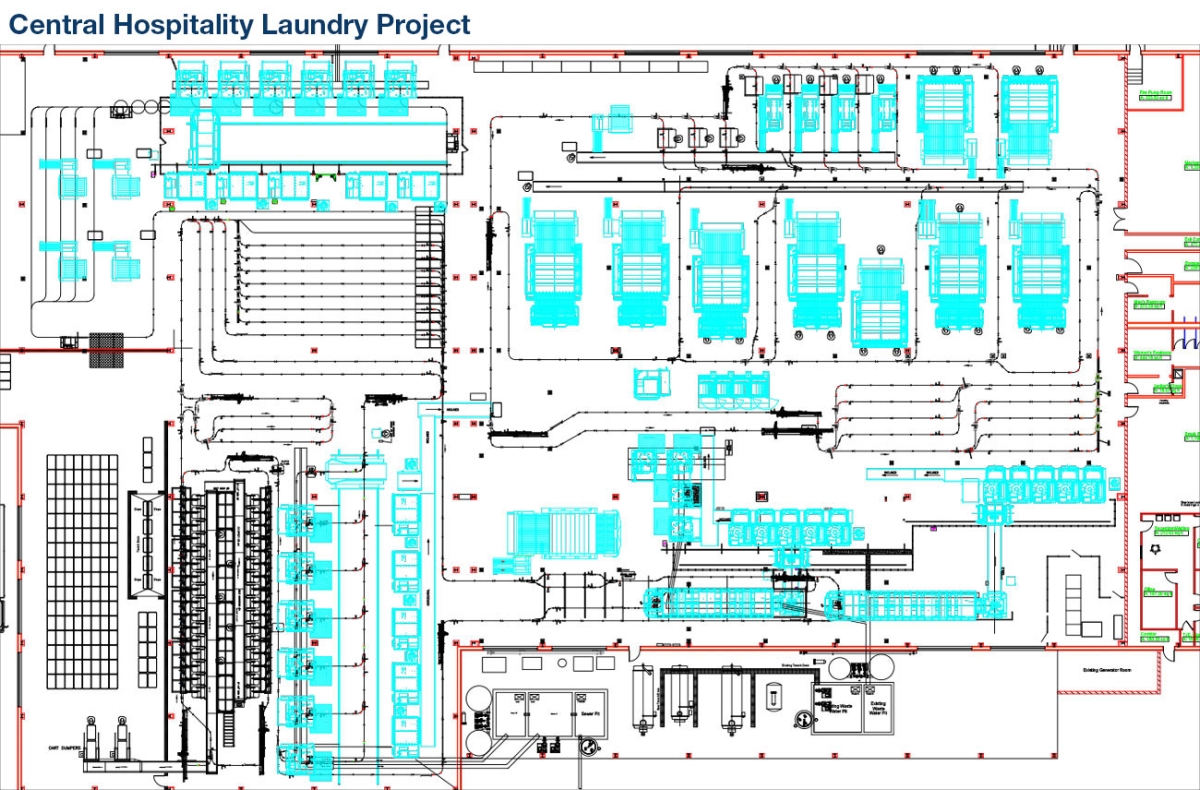

The design activity is key to review the material/process workflow but also validates existing utility and site infrastructure concerns for the project. In a perfect world, the equipment layout would begin with a ‘blank canvas’ and the concepts created by an architectural/engineering firm to design a laundry that best suits the needs of the customer. The optimization of the building space and utilization of the ‘cube’ would be taken into consideration to support the initial production processing volume as well as the strategic vision for business growth. Unfortunately, this ideal situation seldom occurs with laundry projects.

Most projects fall into the categories of expansion or renovation/retooling. These types of projects are the most complex given the need to maintain levels of production during project implementation activity. In some cases, a compromise must be made between supporting existing processing requirements and the project implementation. At Braun, we understand these unique challenges and partner with our clients to execute equipment installation projects in the safest and most cost-efficient manner.

During site assessments of existing facilities (whether it be healthcare, linen, or industrial plants), many operations are in older buildings with limited space to expand. Future expansion and strategic growth were likely not taken into consideration when the initial facility layout was completed.

Floor space is a precious commodity in a laundry. Yet, we discover batch tunnel washer systems set into building corners with no room to expand production capacity or replace aging equipment. Also, we find building additions that have been incorporated over time to accommodate new equipment to process additional capacity without considering process flow. Plants that have been expanded in this manner tend to resemble complex jigsaw puzzles.

Often these expansion efforts were not well positioned to support the needs of the operation strategically. Sometimes in the haste to address immediate equipment liabilities and/or process shortcomings, decisions are made that negatively impact the operation over time. This is why Braun believes in a thorough analysis and a comprehensive design approach in concert with the customer’s immediate processing requirements and future strategic vision. In this manner, all future business objectives are taken into consideration before implementing a solution.

It is important to place significant emphasis on designing processing solutions that will afford the operator the ability to grow the business without extensive capital expenditures for the concrete and steel necessary to construct additional operating space. Therefore, it is important to take into consideration strategic growth by allocating operating “space” for future equipment. Typically, Braun will illustrate future machines in the layout design as this approach provides a clear understanding where additional equipment is to be installed and integrated.

The majority of the time expended during the laundry design process is determining the current and future production requirements, the most efficient manner in which to process the goods, and the optimal fit of the equipment.

When designing a new facility, a number of criteria should be taken into consideration for a successful outcome. It is vital to understand the process flow of a facility, so equipment is placed in a configuration that optimizes material handling while allowing ample space for projected future expansion. An institutional laundry facility is no place for experimentation or guesswork. Not only has the Braun team accumulated decades of proactive experience, they’ve also embraced and shared the most innovative design tools and techniques. The use and knowledge of AutoCAD drawings and Building Information Modeling (BIM), plus other revolutionary approaches, will bring to life accurate buildouts of the proposed facility, supporting informed decisions about materials, capital expenditures and infrastructure – before the first shovel hits the ground.

Ceiling heights will need to be designed and specified with adequate above finished floor (AFF) clearance to accommodate monorail systems. Utility systems (electrical & mechanical) need to be provided for all necessary equipment and incorporate future growth needs in the design process. Chemicals, linen storage, loading docks, office space, maintenance areas (for equipment as well as fleet), employee locker rooms and rest rooms should also be taken into consideration with ample space provided. Parking and exterior access to the building for deliveries and material off-loading are often overlooked. This includes the routing and staging of various route trucks and large bulk transport vehicles on the facility property.

Customers are often looking for a solution to address their inability to meet production goals. Often, they simply want to add equipment to address this need. This may not always be the appropriate approach. Workflow may not be the first thing on a launderer’s mind, but it may be the answer to address their inability to meet goals. Analyzing the flow of goods in and out of a laundry plant, reviewing the production metrics and determining the equipment needed, along with incorporating material handling systems may be the best solution operationally, and this will undoubtedly be the best solution financially.

Increasing the automation level of an existing laundry facility certainly improves plant throughput. There has been an increase in customer interest to include more material handling with conveyors and monorail systems to reduce the number of carts; FTEs and non-value-adding handling. Braun has been partnering with third-party rail providers for more than 25 years for automated loading of batch tunnel washers and conventional washers. It is important to consider and review the potential to incorporate material handling solutions for clean goods which includes rail routing and staging to finished goods areas for flatwork and small piece processing.

These types of project submittals are key given the analytical details incorporated with the presentation materials so that the business owner can make important strategic decisions. It is also important to note that in most cases, many improvements are not completely captured in the ROI calculations. These include increased wash and finishing goods quality; better employee ergonomics; reduction in chemistry and potential reductions in linen replacement costs.

When you are choosing an equipment provider, your project will move smoother if the provider has the contacts and working relationship with suppliers from all aspects of your project build. Braun has the ability to partner with multiple 3rd party contractors ranging from general contracting companies to rail providers and process pipers to provide complete turn-key laundry projects.

Consider also that laundry re-tools require minimal machine downtime and extremely tight schedules. Through the use of tracking tools and the selection of qualified 3rd party partners, Braun has a proven track record of successfully executing these types and other types of projects – from single-point solution installations to on-premise facility projects, new construction of complete laundry plants and multiple system (BTW and Open Pocket) automated plants. Braun completes more than 150 projects annually in high-profile facilities across each market segments in the laundry industry.

If you select Braun as your equipment provider, our Project Management Team would work very closely with the laundry team in determining and completing the final scope of work for the project. Once the scope of work has been finalized, the Project Manager is responsible for the equipment layout drawings, foundation/trench detail drawings, equipment utility schedules, rigging plans, equipment installation details for MEP and any further submittal documentation required. Additionally, our Project Manager would interface directly with the retained architects, electrical and mechanical contractors, installation/rigging contractors, and utility systems engineers throughout the lifecycle of the project.

Our goal is to complete value adding projects on-time and on budget, safely and in line with the goals and expectations of our client partners. A successful project – with positive impact on the bottom line – demands strong partnerships with leading brands who provide meaningful support. For example, Braun is a time-tested laundry equipment manufacturer known for both world-class systems and stellar working relationships.

by Cliff Quick, Director of Inside Sales and Project Management and G.A. Braun Inc.