Reducing Downtime in Industrial Laundries: The Power of Proactive Maintenance

Minimizing equipment downtime is essential for maximizing productivity and extending the life of your industrial laundry equipment. A well-executed proactive maintenance (PM) program is the most effective way to prevent unexpected breakdowns, reduce repair costs, and support long-term operational efficiency.

What Makes a Strong Proactive Maintenance Plan?

An effective PM program should be tailored to your facility’s unique operational needs and include the following elements:

- Skilled employee training and onboarding

- Clear site housekeeping procedures

- Engineering team training and documentation

- Task-based risk assessments

- Access to external support resources

- Verified local contractor and OEM contacts

- Comprehensive preventive maintenance schedules

- Operational cost and trend tracking tools

- Contingency plans for operational disruptions

The Role of Engineering in Reducing Downtime

A successful PM strategy starts with the chief engineer, who defines the long-term maintenance plan, sets the budget, and ensures resources are aligned. Plant engineers manage the day-to-day execution, coordinating closely with production teams to support equipment health and minimize downtime.

Even with proactive plans in place, equipment issues can still arise. That’s why it’s critical to have a well-documented contingency plan and reliable service contacts on hand—whether for in-house fixes or external repair support.

Building an Equipment Wellness Program

Modern wellness programs use maintenance software to streamline PM tracking and automate work order management. These systems evolve with the needs of the facility and centralize all maintenance data in one easy-to-access location.

Key elements of a wellness program include:

- OEM maintenance manuals outlining service intervals and components

- On-site inventory of essential spare parts for quick repairs

- Daily, weekly, and monthly PM schedules

- Hours-of-operation-based service milestones

If you’re unsure of what parts to keep on hand, most manufacturers can provide a recommended spare parts list tailored to your equipment.

Technology and Diagnostics Improve Equipment Longevity

Today’s commercial laundry machines are equipped with advanced touchscreen controls and intuitive diagnostic tools. These platforms (PLC or PC-based) simplify troubleshooting and provide clear performance insights—eliminating guesswork and enhancing operator confidence.

Many OEMs also offer remote diagnostics, wellness contracts, and technical support services to help supplement your internal maintenance team and reduce long-term costs.

Benefits of a Proactive Maintenance and Wellness Program

- Extended machine life

- Reduced unplanned downtime

- Improved system diagnostics and planning

- Consistent software updates and control upgrades

- Better team skill development and retraining opportunities

By identifying small issues early, a PM program prevents minor problems from turning into major, costly failures.

Operator Training: The Foundation of Equipment Reliability

Proactive maintenance is most effective when paired with comprehensive training. Initial and ongoing training sessions help operators, engineers, and supervisors:

- Understand machine functionality

- Master control interfaces and diagnostic tools

- Improve productivity through proper machine usage

Training also strengthens the relationship between the laundry facility and the equipment manufacturer, ensuring continued support and education.

Final Thoughts: Be Proactive, Not Reactive

Investing in proactive maintenance and training reduces long-term costs, protects equipment, and ensures consistent production. Whether you’re maintaining current operations or preparing for future growth, a robust wellness and PM plan is key to reducing downtime and maximizing ROI.

Looking to optimize your facility’s maintenance strategy? Contact GA Braun for expert guidance, wellness programs, and service support tailored to your laundry operation.

(l/r) Metro Laundry’s Chief Engineer Mark Proctor; COO Steven Young; and Plant Manager David Slawson stand by the plant’s upgraded sheet feeder.

Hospitality laundry operators have struggled since the COVID-19 pandemic hit in March and slowed hotel bookings to a crawl. But many have seized the opportunity of a slowdown to prepare for a time when their prospects improve. Metro Laundry Service, a Washington, DC-area hotel launderer, recently collaborated with G.A. Braun Inc. on an upgrade of three sheet feeders aimed at doing just that.

Before COVID-19, Metro Laundry was growing rapidly. A second, 52,000-square-foot plant opened in 2018 with great fanfare as the business expanded. When the pandemic hit, business plummeted by as much as 95%, said COO Steven Young. The second plant, dubbed “MLS 2” was shuttered by early April. Operations were consolidated at the company’s original 24,000-square-foot plant in Capitol Heights. Among other down-time projects, discus-sions among the Metro managers and its executive team centered on making improvements to three Braun sheet feeders. The supplier company, based in Syracuse, NY, seized the opportunity to fine-tune its equipment. During the week of Sept. 28, it installed a newly upgraded feeder to replace one that Metro had. Young and his team are delighted with the revamped feeder and look for-ward to having the same upgrades applied to two other feeders. “Braun is a very valued partner of ours,” Young said. “They were part of the opening of that MLS 2 plant, and they wanted to be a part of helping MLS survive COVID and revitalizing the original plant. We’re very thankful to them for that.”

Mark Kirby, Braun’s director of finishing equipment technology, returned the compliment, thanking Metro for its collaborative input as a win-win for the company and its supplier. “Braun partnered with Metro Laundry to help define action items during the planning and development of Braun’s next generation of the Precision Series® Spreader/Feeder,” Kirby said. “Feedback and observations from Metro were well received by our engineering team. This collaboration produced positive results for all involved in the spreader/feeder upgrade.”

Braun’s team of engineers arrived at Metro on Sept. 27 to install the new feeder. The upgraded machine includes fault detection and the company’s patented spread-detection device, re-engineered spread clamps and more.

The Braun tech experts stayed at Metro through Sept. 30. Young said his team was pleased to have them explain the up-graded machine and provide on-site training in other areas. This was particularly helpful because as part of the consolidation of the two plants, older equipment at MLS 1 was phased out in favor of newer equipment moved from MLS 2, Young said. Most of the executive and engineering staff at MLS 1 had limited knowledge of the equipment from the other plant. The feeder installation gave them an opportunity to learn. “During that time that they were here, a stretch of about four days, was an opportunity for our maintenance and mechanics and engineering teams to pick their brains and learn as much about the equipment as possible,” Young said. Now as hotel business begins to pick up, fueled by Washington, DC-area events such as the recent Prayer and Black Lives Matter marches, Young is feeling optimistic that Metro will weather the storm of COVID-19 with a revitalized plant and staff. “We took this situation and tried to turn a negative into a positive and say, ‘Hey, let’s just use this as an opportunity to revitalize the plant,’” he said. “Revitalize it from an equipment standpoint and from a staffing standpoint.

Now we have more maintenance coverage and management than we had before, which has taken some pressure off all of us, so to speak. It allows us to operate better. There’s still a lot of challenges. We’re adjusting as we go along.”

‘YOU’VE GOT TO BE INNOVATIVE’— Q&A with J.B. WERNER

G.A. Braun CEO describes coping with COVID, recruitment/retention challenges and more

By Jack Morgan

In recognition of the 75th anniversary of G.A. Braun Inc., Syracuse, NY, Textile Services recently clicked into a Zoom interview with J.B. Werner, Braun CEO and board chairman. Our discussion ranged over the impact of COVID-19, market trends, regulatory hurdles, overseas expansion and more. Excerpts—edited and condensed for clarity—follow.

Fourth-generation CEO J.B. Werner, photographed in his office at the G.A. Braun manufacturing plant in Syracuse, NY., is enjoying the company’s 75th anniversary. Innovation is the key to its future, he says.

We hear that a lot of your customer base have deferred on machinery purchases or any capital expenditures due to the uncertainty of the pandemic. With various states opening up, is that likely to change in the second half of ’21?

We’re going to see some pickup on the uniform side, but they’re almost back to where they were pre-COVID. The hospital side’s still down but improving. Obviously, the linen in hospitality is down. I think we’ll see a pickup in hospitality, but more toward the resorts because people can’t wait to go out on vacation. The hotels that cater to business travelers, I think that’s going to go down. Businesses are going to do more Zoom meetings and not traveling as much compared to pre-Covid levels.

Any improvements planned for your manufacturing facility?

We opened the first building 2009 and then we put in the addition and doubled it in 2015. We’ve continued to invest in capital equipment in the factory for fabrication and those types of things. We could expand if we wanted to. We’ve got land to do that. We have no plans to do so at this time.

With no Clean Show this year, how have you changed your approach to marketing your equipment and systems?

It gives us an opportunity. Every two years it’s difficult to come up with new equipment…We’ve got a lot of new product development going on, which if we had the show this year, we wouldn’t be able to show as many new products. By the next clean show, we’ll have a number of new products that we will showcase.

You’ve said people at Braun are happy to be working there. Has that made recruitment/retention better? Have you seen less turnover, or is it any easier when you need to hire an engineer?

At times recruitment can be challenging but we are active with local vocational schools and universities in the area. We provide tours, explain what we do and provide an overview of the industry. We’ve found this approach to be extremely beneficial.

Are you sending sales reps out? I’ve heard with some companies, it’s all phone or “Zoom calls.”

Yes, our sales representatives are all traveling. No question.

How about your pursuit of overseas markets? Has that been affected by COVID particularly?

Yes. Especially the Far East. I think they’re still pretty closed down. We’re seeing some activity in Korea. Central and South America, and we continue to be very active in those areas.

How about supply chain? Have you had issues getting parts?

No. Because all of our suppliers are U.S. based it was rare if we ran into an issue and have had little disruption.

Your factory is ISO certified. Does that give your sales reps any competitive advantage when they’re pitching your equipment?

- Definitely, ISO practices contribute to making the development, manufacturing, and supply of products and services more efficient and safe. I’m not sure who is even ISO certified here in the states. I don’t think there are any ISO-certified laundry equipment manufacturers.

When you do your proposals, do they put that into the proposal? Do they ask about ISO certification when you’re bidding it now?

Some do. More of the government RFPs (request for proposals) will have that.

Is government contracting a significant part of your business?

We do a lot of VA (Veterans Administration) business. We always have. That’s always been a strong point of our company. Yes. A lot of the RFPs have what’s called a “Made in America” clause, not all of them, but many do. With the current administration’s push to “Buy American” I believe we will see more of this.

How do you feel about making it to 75 years in this highly competitive business?

We’re very excited about it. We’re very proud to have 75 years in this business. There are not many companies that can say that. Having four generations basically, if you start back from the Prosperity Company, the chemical company (see related story on pg. 40), I’m the fourth generation in the laundry business. The third generation in the company for Braun.

Looking past COVID, what would you say is the biggest challenge that Braun is facing in the next 15-20 years?

You’ve got to be innovative. You got to keep coming up with new products. If you don’t, the market will pass you by. That’s where we focus. Every year, we get together, gather industry input as to what needs are out there and what they would like to see. Then we talk about different products that we should consider building, and make plans accordingly, depending on which ones we decide we’re going to go ahead with. We’ve several brand-new products coming out between now and the Clean Show (July 30-Aug. 2, 2022, Atlanta) and we are looking forward to showcasing them.

Case Study: Clean Uniforms and More! Modernizes New Bedford Facility with Braun Equipment

Case Study: Clean Uniforms and More! Modernizes New Bedford Facility with Braun Equipment

For over a century, Clean Uniforms and More! has delivered top-tier uniform and textile services throughout the Northeast. With more than 100 years in operation, their continued success is a testament to a company culture built on quality, reliability, and continuous improvement.

When it came time to upgrade their aging wash alley at the New Bedford, MA facility, Clean Uniforms once again turned to GA Braun—reaffirming a partnership that began nearly 24 years earlier. The original Braun open pocket wash alley, still operating daily with over 30,000 hours on some machines, was a testament to both Braun’s equipment durability and Clean Uniforms’ commitment to preventive maintenance.

The Project: Wash Alley Modernization and Capacity Expansion

Clean Uniforms and More! President Mark Bodzioch, with support from Braun’s Northeast Regional Sales Manager CJ Spencer, selected Braun for the retool and modernization of their wash alley. “While others may offer similar designs, no one matches Braun’s proven track record of safety, efficiency, cost-effectiveness, and equipment longevity,” said Spencer.

Phased Implementation for Zero Downtime

Because Clean Uniforms needed to remain fully operational throughout the upgrade, the retool project was divided into carefully planned phases. Braun worked collaboratively with the Clean Uniforms team over a five-year period to:

- Design the upgraded wash alley and scope of work

- Develop a detailed work breakdown schedule

- Coordinate equipment delivery, rigging, and installation

- Integrate staff training for seamless operational transition

Braun’s integrated project management ensured that all installation phases aligned with Clean Uniforms’ production schedules. The company coordinated equipment rig-out, freight logistics, and closely partnered with third-party MEP contractors for utility installation.

New Equipment Installation: Boosting Safety and Efficiency

In the first phase, Clean Uniforms’ existing Braun dryers were replaced with high-performance Braun 500PT dryers. The second phase focused on washer and shuttle system upgrades, as well as replacing the soiled rail system to further improve efficiency and safety.

Braun replaced the older 400 series open pocket washers with the space-saving N2 design—allowing the addition of a new washer within the same footprint. The new washers were integrated with a chute-load rail system, eliminating the need for manual loading inside the wash alley. This enhancement drastically improved safety and automation.

Braun’s versatile chute load design worked seamlessly with Clean Uniforms’ preferred rail provider, showcasing Braun’s flexibility and commitment to tailored integration.

Results: Improved Throughput, Safety, and Labor Efficiency

“In several phases, Braun was able to replace the dryers, washers, shuttle, and upgraded discharge conveyors—all while keeping Clean Uniforms and More! running with only minor weekend interruptions,” said President Mark Bodzioch.

Key Outcomes:

- Labor requirements reduced

- Production increased by 3 loads per hour

- Enhanced operator safety with chute load system

“Our goal is always to complete projects safely, on time, and within budget,” added Cliff Quick, Director of Inside Sales and Project Management at GA Braun. “We pride ourselves on executing based on our clients’ goals through detailed consultation, design, and installation.”

Is Your Facility Ready for a Retool?

Whether upgrading aged equipment or preparing for future capacity, Braun delivers high-efficiency laundry solutions customized to your operational needs. Contact us today to learn more about modernizing your laundry facility.

Article By: The Laundry Ledger

Braun’s Director of Marketing, Pamela Simonetti will retire on July 19th and Braun is welcoming Traci Anelli to her new role as Simonetti’s replacement.

As Braun’s Director of Marketing for 26 years, Simonetti was responsible for the development of the strategic planning and full tactical implementation of a wide variety of Marketing programs. They range from the company’s worldwide Corporate Communications Brand Management to advertising, eMarketing and digital platform programs, video production, publicity and public relations programs, and exhibit and conference management.

She is highly respected in our industry by customers, industry associations and other laundry equipment manufacturing professionals.

“I have been successful in managing my extensive portfolio of marketing efforts because I’ve had exceptional support from our engineering team, project management and service organizations,” says Simonetti. “Additionally, I’ve been fortunate to align with an effective external network of marketing communications support teams. I will always be grateful to the many people in the industry who helped me along over the years.”

Prior to Braun Pam served in several marketing and corporate communications positions within Eastman Kodak Company in Rochester, NY, NYC, NY, and Charlotte, NC. Simonetti plans on spending time with family, golfing, boating and enjoying her many other hobbies.

Simonetti is leaving Braun’s marketing programs in very capable hands. Taking the reins is Traci Anelli who joined the company as Director of Marketing in April, 2024.

Anelli graduated from the State University of New York at Fredonia with a Bachelor of Science in Communications/Video Production. She studied journalism abroad at Bond University in Australia, and earned a Product Marketing certificate from Cornell University.

Before joining Braun Anelli was the U.S. Marketing & Communications Manager at Marquardt, a global leader in developing and manufacturing electromechanical and electronic switches and systems for the automotive, power tool, and home industries.

“I am honored to join Braun and lead the marketing efforts of such a respected, industry-leading company,” said Anelli. “Pam has set a high standard with her remarkable contributions over the past 26 years. While these are indeed big shoes to fill, I am eager to bring my experience and fresh perspective to the talented team at Braun. I look forward to building upon the strong foundation she established, driving innovative marketing strategies, and achieving new milestones for the company.”

GA Braun recently completed a major renovation of an operational healthcare laundry facility in Upstate New York, upgrading key processing and finishing areas while maintaining full production throughout the project. This high-efficiency laundry upgrade demonstrates Braun’s proven ability to execute complex retrofits with precision, safety, and zero disruption to customer operations.

Scope of Work: End-to-End Equipment Replacement and System Modifications

The comprehensive renovation included:

- Complete replacement of wash deck equipment

- Modifications to the staph barrier wall for enhanced hygiene

- Clean rail system upgrades

- Blanket and small piece folding equipment replacements

On the wash deck, Braun installed:

- (1) Braun 800NMTDPV-6 Medicare Top Side Loading Washer/Extractor

- (2) Braun 400NMTVP-3 Medicare Top Side Loading Washer/Extractors

Utility connections for all new wash deck equipment were replaced with updated services. The original masonry staph barrier wall was removed, modified, and rebuilt with glass panels, improving visibility and maintaining sanitary separation.

Finishing Area Enhancements for Healthcare Compliance and Throughput

On the clean side of the laundry, Braun installed a new high-capacity blanket system:

- Braun PSSF-130 Precision Series Spreader/Feeder

- Braun NIPF3CF/B-130 Precision Series Non-Iron Blanket Folder

- Braun BLPS-1 Precision Blanket Stacker

Additionally, two (2) Braun SPFRFM Precision Series Return-to-Feed Small Piece Folders were installed. To accommodate this finishing equipment, Braun rerouted and upgraded the clean rail system and provided all new utility connections.

Phased Execution with No Interruption to Production

Maintaining full operational capacity throughout the renovation was a critical requirement due to the healthcare laundry’s role in servicing regional healthcare facilities. Braun developed and executed a phased installation schedule, performing work during off-hours and weekends to avoid any service disruptions.

Strict clean/soil separation protocols were enforced throughout the renovation, including during the replacement of the staph barrier wall, to ensure full hygiene compliance at all times.

Project Delivered On-Time and On-Budget

Thanks to strategic planning, close coordination with the healthcare laundry staff, and diligent collaboration with third-party contractors, Braun delivered the renovation on-time and within budget—meeting every performance and compliance benchmark.

“When Braun commits to an installation timeline and scope of work, we take great pride in our diligence, our proven procedures, and the resources that we leverage to complete our projects,” said Adam Thomas, Braun’s Technical Sales Manager. “From single equipment replacements to full plant retrofits, Braun will support all aspects of a customer’s laundry project.”

Need to Upgrade Your Healthcare Laundry Facility?

From efficient layouts to high-performance equipment and zero-downtime execution, GA Braun delivers full-service laundry renovations tailored to the healthcare sector.

Contact GA Braun today to start planning your facility upgrade.

Maximizing Efficiency and Capacity in a Landlocked Facility: A Braun Success Story

Maximizing Efficiency and Capacity in a Landlocked Laundry Facility: A Braun Success Story

In commercial laundry operations, maximizing efficiency and increasing capacity are critical to staying competitive—especially in space-constrained environments. That’s the challenge Braun’s Project Management Team tackled in partnership with Service Uniform at their Englewood, Colorado facility, located in one of the fastest-growing markets in the U.S.

With aging equipment and a facility boxed in by limited square footage, the Service Uniform plant needed to significantly increase throughput—without adding labor or relocating. Through a multi-phase strategic approach, Braun helped transform the site into a modern, automated production facility capable of handling nearly double the volume.

The Initial Challenge: A Landlocked Facility with Aging Equipment

When Braun began working with Service Uniform in 2018, the goal was clear: increase processing capacity despite physical limitations. During the initial site visit, Braun’s team evaluated the equipment layout, infrastructure, and potential expansion opportunities. One of the most impactful suggestions involved relocating the boiler room to free up valuable interior space.

A Strategic Upgrade Plan for Long-Term Efficiency

Braun developed a comprehensive facility upgrade plan that included:

- Up to five (5) Braun 450 lb. Open Pocket Washer/Extractors

- Three (3) 500 lb. Pass-Thru Dryers

- One (1) dryer bypass conveyor

- Braun OPSH Automated Shuttle System

- Clean goods takeaway conveyor

The layout allowed significant capacity growth within the existing footprint, reducing reliance on manual processes and maintaining current labor levels while preparing the plant for future expansion.

Automating the Wash Alley: Reducing Labor by 50%

Another major pain point was the original wash alley—a labor-intensive setup using six Braun washers and three non-Braun dryers. Braun proposed replacing five washers and integrating an automated shuttle system to optimize transfer times and labor usage.

Because the original dryers were not Braun models, the shuttle system required a custom design to ensure seamless integration. This upgrade, completed in Spring 2023, reduced labor in the wash alley by 50%, streamlining operations and increasing efficiency.

Project Management and Seamless Execution

Braun’s Senior Project Manager, Joshua Risewick, coordinated all aspects of the renovation—from equipment layouts and spec sheets to permit-ready architectural drawing packages. Working closely with contractors and Service Uniform’s internal team, Braun ensured:

- Timely equipment delivery and installation

- Minimal production disruptions

- Smart scheduling around daily operations

- Custom coordination with MEP contractors

“Through multiple phases and extremely detailed planning, we were able to integrate two Braun shuttle systems into a building where previously there had been none,” Risewick said.

Results: Increased Capacity, Reduced Labor, and Improved Workflow

Thanks to Braun’s phased approach and use of high-efficiency equipment, Service Uniform realized several key benefits:

- Doubled wash capacity without expanding the building

- Improved workflow and reduced manual labor

- Faster transfer times and enhanced quality control

Dennis Tschida, Corporate General Manager at Service Uniform, shared this feedback:

“The new Braun open pocket washer/extractor system enhances labor efficiencies through its streamlined design and automation. Since the new equipment was installed, we’ve optimized our workflow and reduced manual tasks, improving overall productivity.”

“Braun’s commitment to excellence and collaboration has exceeded our expectations. We look forward to a continued partnership and future growth.”

Is Your Facility Landlocked But Ready to Grow?

Even in space-restricted environments, efficiency and capacity gains are possible with the right planning and equipment. GA Braun specializes in designing solutions for landlocked laundry operations—delivering custom layouts, automation, and project execution that maximize ROI.

Contact GA Braun today to explore how we can help reimagine your facility for greater throughput, efficiency, and success.

A fire destroyed a three-year-old Braun Triple Sort Small Piece Folder at Warrensburg Laundry (Warrensburg, NY). In just 8 weeks Braun delivered a brand-new folder to Warrensburg.

The triple sort folder plays a crucial role in efficiently processing bath sheets, towels, and incontinent pads. This small piece folder is designed to process and separate these items, ensuring that each customer receives the appropriate linens, optimizing workflow and enhancing overall quality and customer satisfaction.

In the past decade, the population of Denver grew more than twice as fast as that of the U.S. While this meant expanded opportunities for area businesses, it also posed serious challenges for Service Uniform, which was maxing out its production capacity. This issue, coupled with rising labor costs and staff shortages, forced the company to reevaluate its business approach. Ultimately, Service Uniform decided to automate its wash alley with a new Braun Open Pocket Shuttle System. The automation significantly improved transfer times, resulting in greater efficiency with less labor. That, in turn, enabled Service Uniform to boost production to meet current and future demands.

Published in the May 2023 issue of American Laundry News.

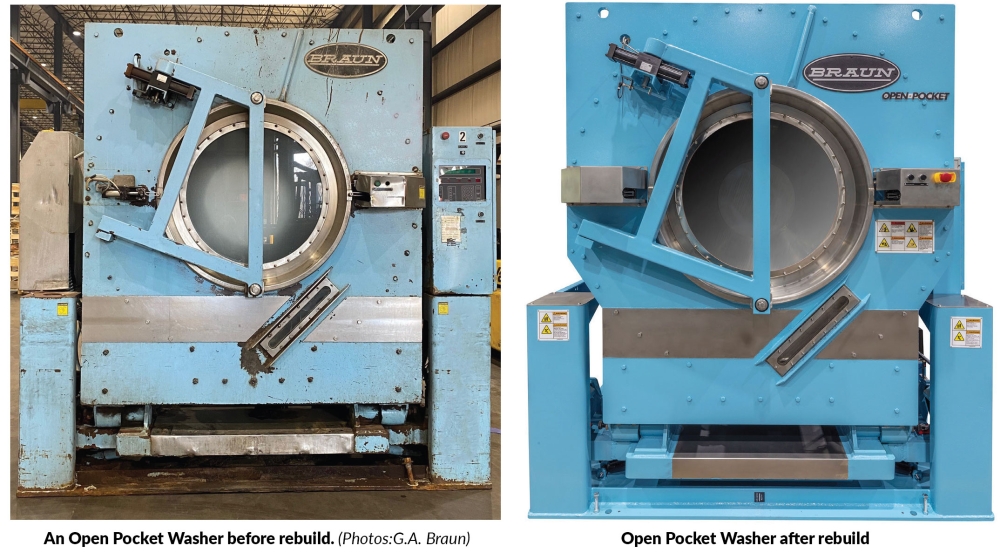

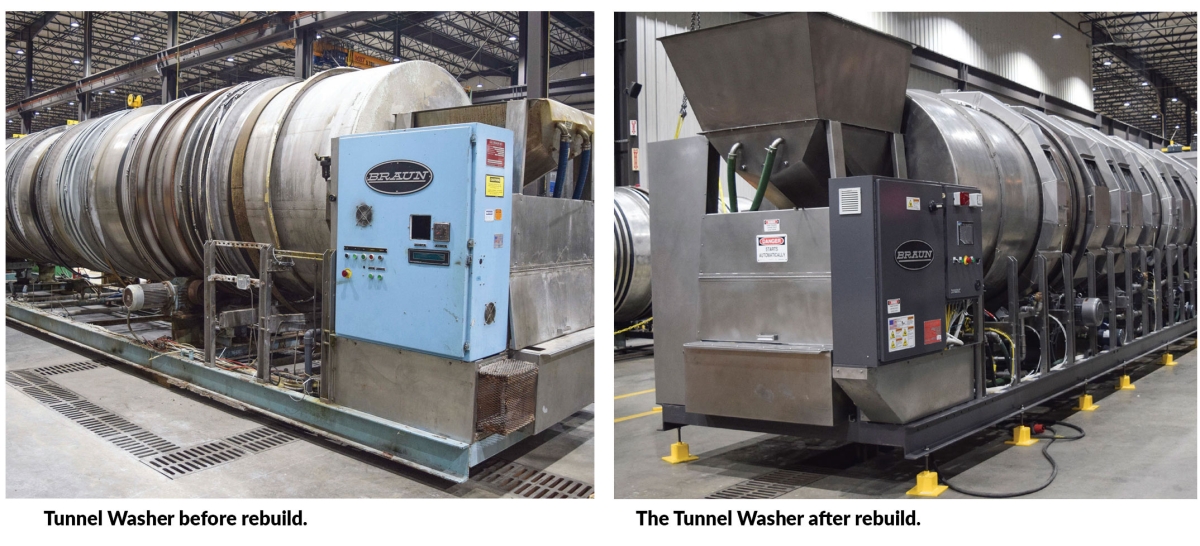

There are three types of pre-owned equipment categories to consider when deciding on a piece of equipment not purchased new from the original manufacturer (OEM).

There is truly “used” equipment that is typically purchased “as is.” Second, there is the equipment purchased from a third party and then “rebuilt.”

Lastly, there is the equipment purchased from the OEM that is rebuilt to the OEM specifications and today’s standards of safety.

The key in each situation is to ask the right questions about the pre-owned equipment. Here are some important questions a buyer in this “as is” situation should try to answer:

How many hours of actual runtime does the machine have on it?

If more than 30,000-50,000 hours, it is likely approaching the end of its useful life without going through a complete rebuild. (Note: 30,000-50,000 hours = 14-24 years of runtime based on a 40-hour week.)

Was the machine purchased new, and why is it being sold?

A thorough inspection should be conducted. Look for any structural issues, evidence of poor maintenance or any functional issues. These are “buyer beware” signals.

Has the machine been maintained and are there records to support this?

No record of preventative maintenance presents a red flag.

Are replacement parts still available for the machine from the OEM or another source?

If not, this is another red flag … especially control parts for an upgrade or retrofit.

Certifications—does the machine have any certifications (i.e., UL, CSA, ETL) and will they remain valid if the machine is purchased and relocated?

Depending on the machine type, certifications could be mandatory by the local municipality in order to run the machine. Most certifications end when the machine is moved to a new location. Obtaining a new certification could be impossible.

Looking at a third-party rebuild? Here are some questions to ask:

Does the rebuilder have references on other like equipment that you can check on?

No references could mean poor workmanship, and the machine may have been repainted but not rebuilt.

Has the machine been completely torn down and inspected for structural issues and repaired as necessary?

If the answer is “no,” or “yes” with no proof, beware.

Are controls and components upgraded to the latest available or even able to be upgraded?

If not, are you able to get parts for what the rebuilder is selling on the machine? Are they obsolete?

Does the rebuilder provide a warranty on the rebuilt machine and components?

No warranty puts you back in the “as is” scenario. If a warranty is not offered, you need to know what is covered.

What certifications are necessary for you to operate the machine in your municipality?

CSA and ETL certifying agencies state that no rebuilder other than the OEM can re-certify a machine to CSA, UL, ETL or similar standards.

Does the third party offer aftermarket support?

If the third party outfitted the machine(s) with custom controls and/or parts, the OEM cannot help support the product when the machine breaks down and requires service. Often the changes that were made are not reversible.

Finally, if you are considering purchasing a rebuilt machine from the OEM, here are some questions to ask:

Does the OEM have references for similar equipment?

If the OEM cannot provide you with references on similar types of rebuilt equipment, that presents a red flag.

Was the machine completely torn down and inspected for structural issues and repaired as necessary? Does the OEM provide a warranty on the rebuilt machine?

If it was not, there’s a good chance that the warranty, if any, will be limited.

Were all components and controls updated to the latest available platform and updated safety features?

If they were not, can you obtain replacement parts in the future through the OEM or another source? If the answer is no, you have cause for concern.

Does the OEM offer service and technical support?

This is an obvious benefit for the long-term health of your investment. Whichever scenario you chose, take the time to do your homework and make sure a bargain is really a bargain.

Sandro Bortoloni, is director of aftermarket operations for G. A. Braun Inc.