JENSEN North America, a subsidiary of the JENSEN-GROUP, is pleased to announce the acquisition of the business of G.A. Braun. This strategic move marks a significant milestone in the growth strategy of the JENSEN-GROUP, expanding its manufacturing footprint, product portfolio, and service network across North America.

Founded in Syracuse, New York, G.A. Braun is a respected supplier with a well-established brand in the laundry equipment market in North America. The acquisition reflects JENSEN-GROUP’s strong commitment to the North American market and its long-term strategy to strengthen local operations and manufacturing capabilities.

With this acquisition, JENSEN gains access to Braun’s state-of-the-art production facility with a strong reputation and a loyal customer base. Both brands will continue to co-exist, building on their respective legacy and customer relationships. This approach allows both JENSEN and Braun to preserve what makes each brand unique, while joining forces to deliver even greater value, innovation, and support to customers across North America.

Supporting growth in the U.S. market

With steady and sustained growth in the North American market, the JENSEN-GROUP aims to further enhance its ability to serve customers efficiently and locally. The integration will bring additional production and advanced technology to Braun’s Syracuse facility. Both companies share a deep-rooted commitment to innovation, quality, and customer orientation. These values have guided their success for decades in the laundry industry.

The newly founded company JENSEN Braun LLC will acquire the assets of G.A. Braun. Under the new structure, JENSEN North America will manage both JENSEN Braun LLC in Syracuse NY and JENSEN USA in Panama City FL.

“Our goal has always been to align production capacity with our sales growth,” confirms Jesper Munch Jensen, CEO of the JENSEN-GROUP. “By expanding our manufacturing base in the USA, we can respond faster to customer needs, shorten delivery times, and continue delivering the high quality and reliability that define the JENSEN brand. We are delighted to welcome Braun’s team into our organization and to grow together, driven by our shared commitment to customer satisfaction and continuous improvement.”

“After many successful years in the laundry industry, I am proud to see Braun become part of the JENSEN team” says J.B. Werner, CEO of G.A. Braun. “We share the same values: customer focus, reliability, and a passion for building long-term partnerships. I am confident that our employees and customers are in very good hands and will benefit from the global strength and expertise of the JENSEN-GROUP.”

Unique passion, unique spirit

People are at the heart of every successful company. The employees of G.A. Braun bring decades of experience, dedication, and craftsmanship. These qualities have earned them deep respect across the industry.

“We are truly excited to welcome our new colleagues to the JENSEN team,” says Tony Biela, President of JENSEN North America. “Their know-how, their customer relationships, and their commitment are invaluable to our shared success. Together, we will build on our strengths and create new opportunities for growth, innovation, and personal development.”

“This acquisition combines two strong organizations with complementary strengths,” adds Jesper Munch Jensen. “Together, we are well positioned to support our customers throughout North America with an even broader range of products, services, and technologies.”

For over 75 years, Braun has been a proud member of the Textile Care Allied Trades Association (TCATA)—a partnership rooted in shared values of innovation, integrity, and continuous improvement in the laundry and textile-care industry.

Braun joined TCATA in 1949, just three years after the company’s founding, and the relationship has grown alongside our business. As a family-owned, American manufacturer, Braun has always believed in strengthening the industry through collaboration, education, and the exchange of ideas. TCATA has provided a forum for exactly that—connecting suppliers, manufacturers, and leaders dedicated to elevating quality, safety, and efficiency across all aspects of textile care.

Today, Braun’s continued involvement reflects our commitment to helping shape the future of the industry. From advancements in automation and controls to operator-first equipment design and U.S.-based manufacturing, we value TCATA as a long-standing partner in promoting progress and supporting the success of laundry operators everywhere.

Together, we celebrate decades of shared purpose—and look forward to the next generation of innovation.

G.A. Braun made a major impact at Clean Show 2025, reaffirming its position as a trusted leader in industrial and commercial laundry equipment. With a bold new booth design, 17 machines on display, and a full team of experts on-site, Braun delivered a clear message: the company does not just sell laundry machines — it provides complete laundry solutions to help customers Streamline Your Laundry.

Attendees from around the world explored Braun’s industrial washers, dryers, material handling solutions, and laundry finishing equipment — all designed to maximize efficiency, safety, and reliability.

Unveiling New Finishing Equipment: The Streamline Series™ Ironer

One of the biggest highlights was the debut of the Streamline Series™ Ironer, representing the next evolution in Braun finishing equipment by combining the best features of the Delta and Precision models into one unified design. Built for faster installation, easier serviceability, and intuitive operation, the Streamline Ironer simplifies every stage of ownership.

Its redesigned cabinet and modular roll sections allow for quicker installation, while relocated electrical components improve accessibility and serviceability. Operators benefit from fully updated PLC software with modern graphics, delivering a more user-friendly experience. The Streamline Ironer will officially be available in 2026.

More Than Just Machines: Braun’s Complete Laundry Support

Braun also showcased how smart technology enhances daily operations:

- Braun Rx® is a web-based troubleshooting system that provides machine-specific diagnostic support. When an error occurs, the platform delivers step-by-step instructions along with access to schematics, suggested replacement parts and a library of manuals, photos, and videos. The redesigned system is fully compatible with phone, tablet, and PC, allowing maintenance teams to access detailed guidance anywhere in the facility.

- Washnet® Web gives managers real-time visibility into the wash alley, displaying equipment status, formulas, and productivity data at a glance. It tracks loads, poundage, and cycle times while flagging alarms for fast troubleshooting — even remotely via VNC. With sortable reports by date, shift, machine, or formula, Washnet Web delivers the insights needed to run smarter, safer, and more efficient laundry operations.

Together, these technologies equip operators and managers with the tools to reduce downtime, boost throughput, and make informed decisions.

In addition, visitors were reminded why Braun has been a trusted partner for decades. Beyond equipment, the company delivers:

- Turnkey project management – from design and installation to training.

- Safety-first solutions – including advanced wash aisle safety systems.

- Dependable service and parts – backed by a U.S.-based support team.

- Consultative expertise – helping laundries optimize throughput and ROI.

This full-service approach ensures customers gain not only advanced machines, but also the long-term reliability and partnership that set Braun apart.

Made in America. Built for the Future.

At the show, Braun reinforced its Made in America advantage, giving customers confidence in consistent quality, dependable supply, and long-term support.

Looking Ahead to Clean Show 2027 in Las Vegas

Clean Show 2025 underscored Braun’s dedication to innovation and partnership across healthcare, hospitality, industrial laundry markets, and beyond. Looking ahead to Clean Show 2027 in Las Vegas, Braun remains committed to driving innovation, building strong partnerships, and delivering the best in laundry equipment and smart laundry solutions.

As the industry moves toward more complex, automated systems, Braun will continue focusing on what customers value most — equipment that is durable, operator-focused, and built to Streamline Your Laundry — backed by customer service that is truly unmatched.

People in NYC are used to surprises — but one morning, commuters in Manhattan paused as an entire street was shut down outside one of the city’s historic hotels. The reason? A laundry upgrade was underway, and the Braun team had rolled into town with a mission: to install a three-roll ironer, folder and stacker system for the hotel’s laundry finishing line.

The hotel laundry processes over one-million pounds of hospitality, and food and beverage linens yearly for 140 guest rooms, 49 suites and 80 co-op residences — all with a single-shift team of about a dozen people.

This landmark building posed several challenges for the install. There were tight corridors to squeeze through, marble floors to tread carefully upon, and no standard access from which to load equipment. The demand was high, and the space was tight. That’s where Braun’s precision planning came in.

A Complex, Challenging and High-Stakes Install

Robbie Tippett, project field supervisor, G.A. Braun oversaw the project. His expertise in major installations, evaluating rigging challenges, developing logistical plans, and his unique ability to disassemble, transport and reassemble complex systems with precision made him the man for the job.

Over two years and five site visits, the Braun team engineered a meticulous plan.

“Two pieces of equipment had to be broken down into an unbelievable 16 pieces,” said Tippett. “Then we had to reassemble it using gantry cranes that we had to erect inside of the laundry.”

Each machine was broken down into sub-3,000-pound sections — the largest of which had to be craned through a fragile second-story historic window. From there, the pieces were rolled carefully across a protected marble ballroom floor and guided through narrow back hallways. Finally, the equipment was lowered down an elevator shaft using a custom-installed I-beam for controlled vertical rigging – a process requiring coordination with a third-party elevator company and inch-perfect execution.

Once in the basement, the equipment was reassembled using gantry cranes and a custom sequencing plan that maximized every inch of available space.

Despite active weddings, events, and even construction on the building’s façade, the Braun team worked around the hotel’s schedule — ensuring minimal disruption.

What was expected to take up to four weeks was finished in just two. “For this particular job, we did three days of rigging, and then the next two or three days we spent getting everything assembled, time tested and running,” said Tippett.

The installation was completed safely, efficiently, and with zero incidents. “We probably go a little overboard about safety,” said Tippett, “But you know, I’d rather be safe and have everybody go home at the end of the day.” The hotel team was “amazed” by Braun’s execution and the care, professionalism, and precision behind every project phase.

For Tippett, who’s spent his entire career building and rigging laundry equipment, this job showcased everything Braun stands for: planning, safety, respect for the customer, and getting the job done right — the first time.

By James Galeno-Budion, Written for Laundry Ledger

In July 2023, a devastating fire tore through Indoor Billboard’s laundry facility, bringing operations to a halt. Indoor Billboard partnered with other laundry operations to handle linen and mat processing during their recovery period. Faced with the massive challenge of rebuilding, they turned to G.A. Braun—not just as an equipment provider, but as a true partner in their recovery.

Rebuilding with Braun

From day one, Braun stepped in with expert infrastructure planning, guiding the redesign of Indoor Billboard’s wash alley and ensuring that every piece of equipment was delivered on an accelerated timeline.

By August 2024, Indoor Billboard was fully operational again with:

✔ Three 650 OP Washers

✔ One 450 OP Washer

✔ One 250 OP Washer

✔ Two 700 PT Dryers

✔ A Shuttle System

More Than Equipment—A Commitment to Success

Beyond delivering high-quality, on-time solutions, Braun’s customer support team was with them every step of the way. From design to installation, Braun provided knowledgeable, responsive service, proving that their commitment goes beyond just selling machines.

Why Indoor Billboard Chooses Braun

“We prefer doing business with Braun because they don’t just deliver top-tier equipment—they stand by their customers when it matters most,” said Indoor Billboard Owner, Jim Shulevitz.

GA Braun Wins Best Video and Advertising Effectiveness Awards at 2025 TRSA Industry Awards

WASHINGTON, D.C. – February 6, 2025 – GA Braun has earned national recognition at the 2025 TRSA Industry Awards Dinner, taking home two prestigious honors: Best Video Award and the Advertising Effectiveness Award. These awards highlight Braun’s leadership in strategic marketing and engaging storytelling within the linen, uniform, and facility services industry.

The awards were presented during TRSA’s 15th Annual Legislative Conference in Washington, D.C., where more than 125 industry executives gathered to celebrate excellence in commercial laundry and textile services. Braun’s achievements underscore its commitment to innovation not only in laundry equipment design, but also in how it communicates the value of its solutions to customers and industry stakeholders.

Award-Winning Marketing That Resonates with the Industry

The Advertising Effectiveness Award, based on results from Textile Services magazine’s independent reader studies, recognizes supplier partners whose ads address the industry’s most urgent needs. Braun’s targeted campaigns stood out for their clarity, relevance, and ability to connect with decision-makers in the commercial laundry space.

Recognized Among Industry Leaders

The TRSA Industry Awards recognized 58 honorees across 11 categories, celebrating forward-thinking approaches to business development, customer communication, and operational excellence. Braun’s dual win reinforces its position as a thought leader and trusted OEM partner in the evolving world of textile services.

As the industry continues to grow and adapt to new challenges, GA Braun remains focused on delivering high-performance equipment, supported by marketing that drives awareness, engagement, and results.

GA Braun is pleased to announce the promotion of Joseph Fiacchi to the position of Director of Aftermarket Operations, which became effective September 2024. In his new role, Fiacchi will oversee all aspects of the company’s aftermarket services, including customer support, maintenance, and service operations.

Joseph Fiacchi joined GA Braun in 2011 after earning a bachelor’s degree in mechanical engineering technology from Alfred State College. Since then, he has made significant contributions to the company’s product development and engineering efforts. Fiacchi began his career at GA Braun as a Product Design Engineer and steadily advanced within the organization, most recently serving as Mechanical Engineering Manager.

GA Braun is confident that Joseph Fiacchi’s extensive experience and deep understanding of the company’s products will drive continued success in his new role as Director of Aftermarket Operations.

For more information, please contact Director of Marketing, Traci Anelli, at tanelli@gabraun.com.

Safety is integrated into every aspect of a Braun project. It is a consideration at every stage of project development and execution. Braun is committed to ensuring that all personnel remain safe during all project phases in laundry operations.

The process starts with the initial review of the specific laundry operation during the promotion of a Braun equipment solution. Site assessment includes reviewing unusual hazards or areas of special consideration from a constructibility and risk potential perspective. Risks and hazards identified are researched for alternatives to mitigate exposure. When estimating resources, safety concerns are included. Work plans are reviewed by senior management, including safety personnel, with a goal of reducing employee exposure to hazards.

Project preplanning begins once a specific opportunity is committed to Braun, and resources are matched to project needs. Project Management personnel are selected who have experience and can lead in the field. Equipment is secured that fits best practice for site conditions. Subcontractors are selected who can implement a safe and compliant work plan.

A site-specific safety plan is then developed to match the project. Onsite Project Managers and Project Field Supervisors assume the role of onsite safety management and tailor the plan. Safety rules and regulations are included for anticipated activities. Specifics for personnel, contacts, and local emergency response are inserted.

Project Managers meet with Braun Field Service Technicians and selected subcontractors to discuss project needs. Training requirements are matched to the skill set required for a safe and productive project.

Employees onsite for the first time receive orientation and project-specific training before starting work on the project. Project Managers and Project Field Supervisors manage daily activities and ensure that subcontractors and Braun Field Service Technicians are adhering to the proper safety guidelines. On-site training and mentoring are provided as needed.

Personal protective equipment (PPE) is issued to all employees and subcontractors and is required to be worn by personnel while onsite.Field Service Technicians and Subcontractors meet daily with Project Management, before the workday begins, to review upcoming activities and safety concerns. Jobsite conditions and hazards previously identified are shared by crews working in an area previously.

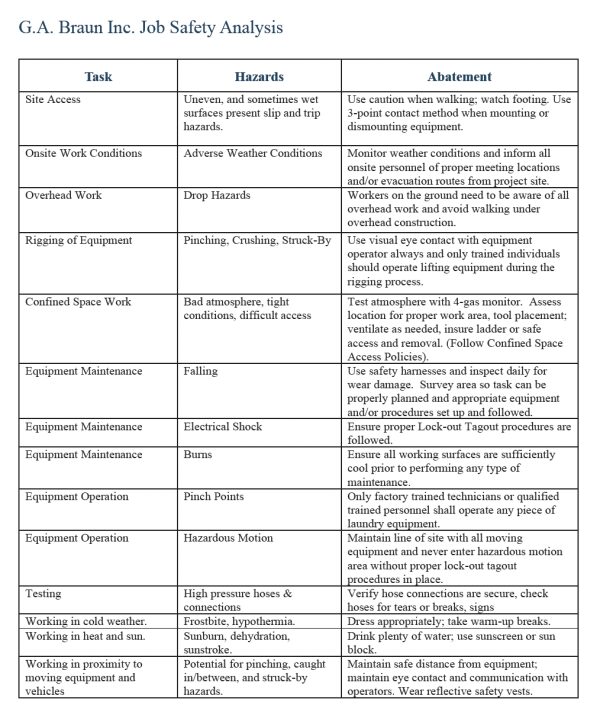

Subcontractors gather each day to complete a Job Safety Analysis and toolbox talk. Conditions and hazards associated with the planned activities are discussed along with the necessary mitigation. A database of activities, hazards, and abatement techniques has been developed by Project Field Supervisors, Project Managers, and safety professionals. Additions are made to the supplied checklist as needed, and onsite personnel sign in to document attendance.

Equipment is inspected each day before use. Fueling and maintenance are performed with proper protective measures.

Daily and weekly project updates are communicated to the Director, Inside Sales & Project Management, as well as the Safety & Environmental Risk Manager. Project status and planned activities are reviewed. Incidents from the previous week are discussed, along with lessons learned, to avoid repeating incidents. The Site-Specific Safety Plan is updated with any changes in site conditions and tasks.

This is an example of a job safety analysis plan from Braun for a recent on-premise laundry project in the healthcare industry:

By Cliff Quick, Director of Inside Sales and Project Management at G.A. Braun Inc.

Learn more in our Project Management Guide: Click Here

Partner with OEM to optimize your processes

In healthcare laundry, infection prevention starts long before clean linens reach the patient. It begins with a scientifically engineered, tightly controlled process that ensures soiled textiles are cleaned, disinfected, and returned free of microbial contamination. Partnering with an experienced OEM like Braun helps healthcare providers optimize their laundry operations for infection control at every step.

Why Infection Control Matters in Healthcare Laundry

Healthcare providers have a responsibility to deliver hygienically clean linen to the facilities and patients they serve. However, maintaining microbial-free textiles requires strict adherence to processing protocols from the moment soiled linen leaves the facility to the time it’s returned clean. Each stage—sorting, washing, drying, finishing, and transport—presents its own risks for cross-contamination if not carefully managed.

Scientific principles play a critical role in ensuring that laundering environments and equipment do not become sources of microbial growth. That’s why infection control starts with proper laundry facility design, operational discipline, preventive maintenance, and process validation—all grounded in time-tested, evidence-based methods.

The Role of OEMs in Infection Control

As an Original Equipment Manufacturer (OEM), Braun plays a key role in helping laundries reduce infection risks. Our equipment is engineered with infection control in mind—utilizing proven material science, chemical compatibility, and operational design to support high-performance processing environments.

Braun’s commitment is to deliver solutions that are durable, easy to maintain, and scientifically validated—not just driven by marketing claims. Whether it’s healthcare laundry or any other high-risk environment, our goal is to provide equipment that delivers consistent, hygienic results across all applications.

Understanding the Science: The Wash Pie Explained

Proper linen processing depends on four key variables: time, temperature, mechanical action, and chemistry—collectively known as the Wash Pie. These variables must be balanced for effective cleaning and disinfection.

Failing to maintain this balance may lead to:

- Poor wash quality and high rewash rates

- Inadequate rinsing or neutralization

- Linen discoloration and shortened lifespan

- Excessive chemical usage and environmental impact

Braun equipment is designed to support the optimal wash pie configuration, ensuring efficient processing without compromising quality or safety.

Batch Tunnel Washers & Infection Control: Braun’s Differentiation

Batch tunnel washers have become a focus in infection prevention due to their high productivity and unique processing characteristics. However, if not properly designed or maintained, they can become liabilities for microbial growth.

Braun’s batch tunnel washers are uniquely engineered to mitigate these risks:

- Mono-Shell Open Helicoid™ Design: Offers pocket-like mechanical action and self-cleaning throughout each cycle.

- All-Stainless-Steel Construction: Non-porous surfaces reduce the risk of biofilm buildup.

- No Dead Spaces: Continuous mechanical cleaning prevents microbial accumulation.

- No Stagnant Baths or Outer Drums: Eliminates areas where bacteria can grow.

- Peroxide-Cured Seals: Exceptional resistance to temperature, chemical exposure, and microbial growth.

- Accessible Components: Easy cleaning and maintenance access ensures ongoing compliance.

- Integrated Heating Systems: Supports a wide range of chemical and sanitation requirements.

- Advanced Data Management: Real-time monitoring of process parameters ensures accountability and validation.

End-to-End Infection Prevention Requires Teamwork

Even with state-of-the-art laundry equipment, infection control is only effective when supported by strong operational discipline. Laundries must ensure:

- Proper facility layout and air flow

- Rigorous separation of clean and soiled zones

- Routine validation of cleanliness and compliance

- Controlled inputs across all stages of the process

It’s important to remember: dryers and ironers should not be relied upon to kill pathogens. True infection prevention starts with managing inputs and process controls, not simply hoping downstream equipment will “clean up the process.”

Consult Your OEM Partner – Maximize Your Infection Control Strategy

At Braun, we encourage healthcare laundries to engage with their OEM partner regularly. Leverage our decades of experience in equipment design and infection control science to get the most out of your operation.

While this article focuses on healthcare laundry, the principles of infection control apply to hospitality, corrections, military, and other high-demand laundry markets.

Science, innovation, and operational excellence are the cornerstones of effective infection control—and at Braun, we’re committed to helping you achieve it.

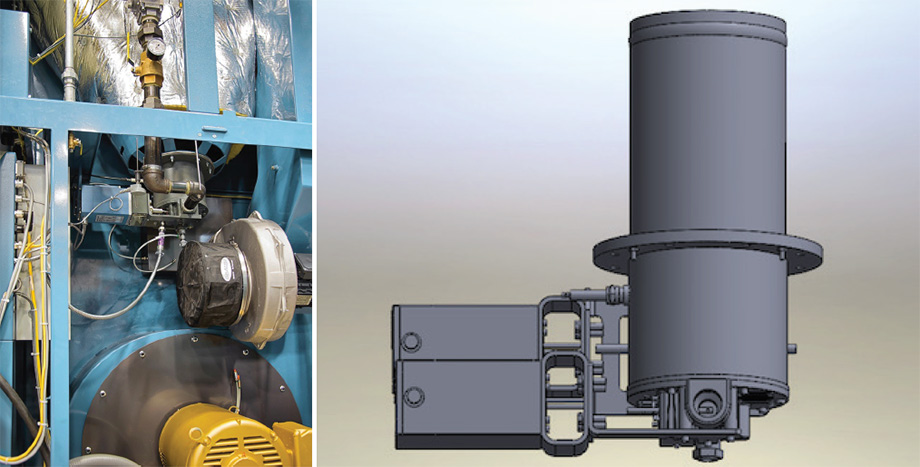

Navigating Industrial Dryer Emissions Compliance in California and Beyond

Tighter Air Emission Standards Are Changing How Industrial Laundries Operate

California continues to lead the nation in environmental regulations, including some of the strictest air emission standards for industrial equipment. While most headlines focus on vehicle emissions, industrial laundry operators—particularly those in Southern California—face growing scrutiny around dryer air emissions, especially NOx (nitrogen oxides) and CO (carbon monoxide) levels.

If you’re an operator looking to replace older dryers with more efficient and compliant models, understanding the latest regulations is critical to making an informed investment and avoiding costly non-compliance issues.

What Operators Need to Know About SCAQMD Rule 1147

The South Coast Air Quality Management District (SCAQMD) enforces Rule 1147, which governs NOx and CO emissions for industrial dryers in Southern California. Under this rule:

- Dryers must emit no more than 30 ppm NOx and 400 ppm CO.

- Equipment with a heat input of less than 2 million BTU/hr, burning only natural gas and processing non-VOC products, may be exempt from air permitting.

Even if you’re not based in California, similar air quality standards are emerging in other states, making this information relevant across the U.S.

How to Choose a Compliant Industrial Dryer

When investing in a new industrial dryer, you must evaluate both performance and regulatory compliance. Here are critical questions to ask your OEM or equipment supplier:

1. Does the Dryer Qualify for an Emissions Exemption?

If your laundry does not process VOC-laden items (like shop towels or bar towels), and your dryer is under the 2 million BTU/hr threshold, it may qualify for an exemption. Ask your manufacturer:

- What is the dryer’s BTU/hr output?

- Can it be detuned to operate below 2 million BTU/hr and labeled accordingly?

- How will detuning affect efficiency and turn times?

Detuning the gas train may impact energy consumption and production rates, so it’s essential to understand these trade-offs.

2. Is the Dryer Truly Low NOx Certified?

If your operation processes VOCs or the dryer exceeds 2 million BTU/hr, you’ll need equipment that complies with Rule 1147 limits.

Don’t rely on marketing claims. Ask your vendor to provide:

- A certification letter guaranteeing compliance with 30 ppm NOx and 400 ppm CO.

- Third-party emissions test results or performance data.

Without this certification, you risk investing in equipment that may not meet local emissions standards—leading to operational delays, fines, or forced modifications.

The Importance of Preventative Maintenance for Emissions Compliance

Once your dryers are installed, compliance doesn’t stop. Most manufacturers only certify emissions during the warranty period and only if the equipment is maintained according to their guidelines.

Key maintenance practices include:

- Daily cleaning of combustion air filters

- Monitoring gas pressure and air-to-fuel ratios

- Routine inspections as outlined in the equipment manual

Failing to maintain the dryer may cause emissions to exceed permitted levels, leading to loss of efficiency and possible re-certification costs.

Avoiding Non-Compliance and Maximizing ROI

Industrial dryers are a major capital investment, and failure to meet emissions requirements can significantly increase your costs. Here’s how to protect your investment:

Do your homework on current and future local regulations

Ask OEMs the right questions before buying

Get written certifications for emissions compliance

Schedule regular maintenance to maintain certified performance

Stay updated on changes to SCAQMD Rule 1147 and similar regulations in your region

Industrial Laundry Emissions Compliance: What’s Next?

As air quality standards continue to evolve, laundry operators across the U.S. must prepare to meet stricter emissions rules—whether you’re in California, Texas, New York, or anywhere in between. By working closely with your OEM and staying informed, you can ensure your dryers are efficient, compliant, and future-proof.

Ready to Upgrade Your Dryers?

Braun offers industrial dryers engineered for low NOx performance and compliance with SCAQMD Rule 1147. Contact us today to learn more or request emissions certifications.

ABOVE: (l/r) Here is a view of a low NOx burner in a dryer; a graphic image of a low NOx burner; on the opening page, there is a group of three low NOx dryers in operation in a plant.