The need for dry folding of small pieces occurs in almost every laundry around the world. There are three basic concepts to tumble dry small parts; manual hand folding, machine folding, or bagging. Each process is as simple as it sounds, but with many different solutions it can be confusing to determine what concept is correct. The end customer’s requirements for quality folded parts, size, and presentation will always establish what process best supports their needs. Hand folding is just that, a slow, labor-intensive process typically used in clean rooms or by exception for a small amount of goods. Bagging is often used in industrial laundries processing large volumes of shop rags or towels where folding is not required. This is a very quick and efficient process.

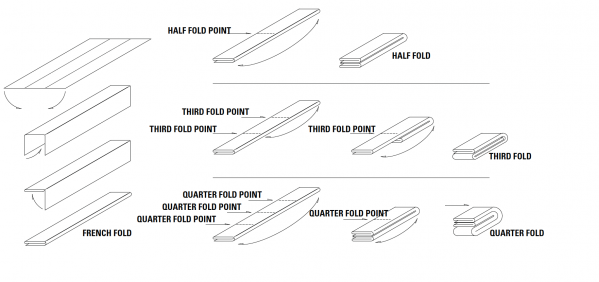

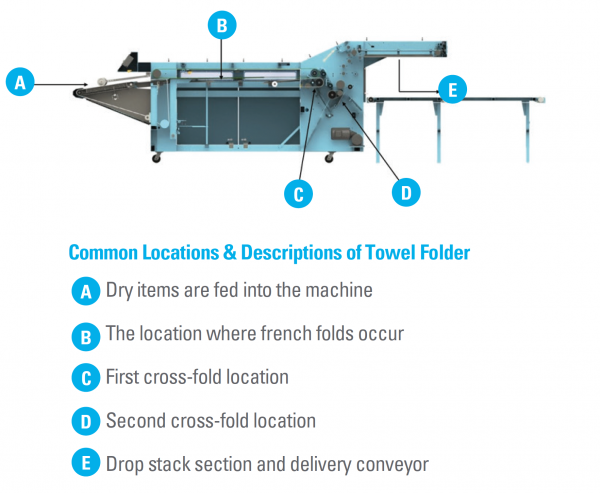

Most small piece folders manufactured today are capable of folding various widths, weights, and types of goods with French fold and two cross folds. Other, more specific engineered equipment, is also available in the market for point solutions and is limited to the specific type of item for which they were designed.

Common Configurations of Towel Folding

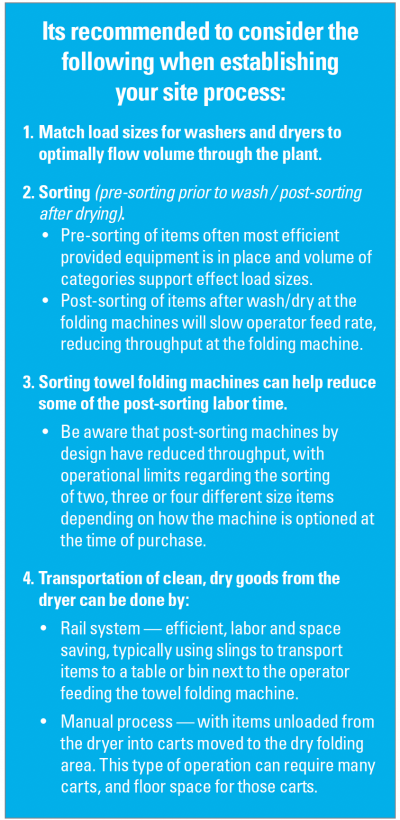

Depending on the capabilities of the laundry and the volume/mix of products to be folded, some sites may elect to presort into categories (i.e. customer’s goods, terry bath towels/mats, pool towels, other than terry products), optimizing the process at the folding machines.

It is important for items to be fully dry before folding them. This especially applies to the hems prior to processing in the folder, or there may be restrictions or jams in machines causing damage to the machine and the product processed. This dry condition also applies to parts like shop rags that are typically being bagged by weight and to avoid the development of bacterial growth or odors.

With respect to the machine folding process, a laundry worker places an item to be folded onto the infeed of the folding machine. Depending on type of folder being used, activation of the infeed conveyor might require the operator to make a second motion activating an input to put the infeed conveyor in motion to start the fold process. Some machine designs support continuous infeed operation, those designs require no user interface other than placing the item onto the infeed conveyor already in motion. As the fed item enters the machine it will be measured, then folded to the desired pre-selected, pre-programed fold configuration, then stacked. Stacks are built in multiples of 5 with varying heights depending on the size of folded part. Commonly, once items are folded the stacks are placed in clean goods carts for delivery to the end users. These carts may or may not be lined with cart liners depending on the user’s requirements. Some end users may require that goods be bundled, wrapped and bagged in stacks of a specific number. Several different delivery methods for transporting stack folded items from the folding machine to carts or pack-out exist. The configuration of purchased dry folding equipment (return to feed, rear discharge or sorting machine) will define this process, methods, or options available to transport folded stacks.

With respect to the machine folding process, a laundry worker places an item to be folded onto the infeed of the folding machine. Depending on type of folder being used, activation of the infeed conveyor might require the operator to make a second motion activating an input to put the infeed conveyor in motion to start the fold process. Some machine designs support continuous infeed operation, those designs require no user interface other than placing the item onto the infeed conveyor already in motion. As the fed item enters the machine it will be measured, then folded to the desired pre-selected, pre-programed fold configuration, then stacked. Stacks are built in multiples of 5 with varying heights depending on the size of folded part. Commonly, once items are folded the stacks are placed in clean goods carts for delivery to the end users. These carts may or may not be lined with cart liners depending on the user’s requirements. Some end users may require that goods be bundled, wrapped and bagged in stacks of a specific number. Several different delivery methods for transporting stack folded items from the folding machine to carts or pack-out exist. The configuration of purchased dry folding equipment (return to feed, rear discharge or sorting machine) will define this process, methods, or options available to transport folded stacks.

Markets Served and Relationship to Tumble Dry Small Piece Folding

Manual processing (hand folding) typically uses a large table with multiple personnel folding goods from piles of clean goods (on a table or in a cart) and stacking them in delivery carts. One person can typically fold and stack 120-200 pieces per hour. Most often found in clean room processing, this type of operation is end user specific. It usually involves hand folding and individually bagging and sealing goods for use in operating rooms or other similar environments. Laundries will have dedicated space for processing these goods and requirements for sterile hygiene and apparel to be worn when working in those environments. The advantage of a manual, dry folding process is that personnel can perform the final quality inspection, and in some cases delint each item as they are folding it. Also, fold quality can be higher as the fold is completed by a human that is constantly correcting and straightening each individual fold during the fold process. Aside from being a labor-intensive process, production rates of one person hand folding goods versus one person feeding a folding machine is not comparable; provided services should be costed accordingly.

Semi-Automated processing or bagging systems are typically found in industrial laundries producing a high volume of small parts (e.g. shop rags or shop towels). The end user requirement for these items is simple; parts need to be clean/dry, and presentation is not a concern. With this process, goods are vacuumed and bagged by weight and delivered to the end user in a bag, reducing labor handling costs. It is important that all items must be completely dry to prevent bacterial growth or development of odor while stored in the bags. Also, operators must consider the cost of consumable bags when totally evaluating this cost and the associated ROI for using this method.

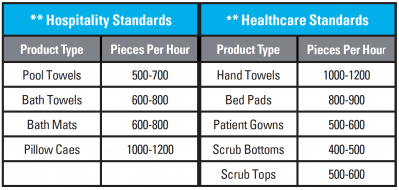

** Standards are based on full dry common sized items. Your piece rate will vary based on internal process, equipment used and product type. Recommened to review your actual tested metrics to this chart.

Folding with a machine works best when items are prestaged in either load slings or laundry bins. Machine operators remove individual goods from the bins and place them on the infeed table of the folder. Parts discharge onto a conveyor in a stack and an operator removes the stack by hand. The stack may be bagged or tied prior to being placed in a clean laundry bin for delivery to the end user. A small piece folding machine operator can feed between 500-1,000 pieces per hour depending on goods type and operator skill level. Another configuration of the same base folding machine is to have all folded/stacked goods discharged onto a take away conveyor. This discharge, when used with a takeaway conveyor, expands the options for tying and wrapping machines. This solution option results in a reduction of material and direct labor, while improving productivity.

Small Piece Folding Machine Configurations and Features

Three most common machine folder configurations are return-to-feed, rear discharge, and sorting by size machines. Equipment manufacturers will keep the base machine infeed, user interface and folding configurations the same with each of the noted configurations. Only changing the discharge or stacking sections to support the item’s needs for movement in the proper direction after folding is completed. Sorting machines will often be longer in length to accommodate various-sized sorting takeaway conveyors. Differences with equipment designs may require machine infeed tables to start/stop with each part. Some will run continuously, while others will pause depending on width changes to the items being folded. Some vendor’s machines have restrictive product ranges, which limit the flexibility of the machine. It is vital that the mix of goods processed best aligns with the machines range of capabilities. This reduces capital equipment cost, improves space utilization, and optimizes the use of available labor.

Return-to-feed machines can have a smaller machine footprint for laundries that have limited floor space. Operators that feed the machine are also removing the folded piece from the stack conveyor and placing the stacked goods in the delivery bin for the end user. This process may have a detrimental effect on machine throughput, as the operator is performing multiple tasks. Items must be sorted by type prior to being fed into this machine. Sorting can occur before or after the wash/dry process.

Rear discharge machines have a potentially higher production throughput, as the operator feeding the machine is not required to multitask and is only concerned with feeding the machine. Folded and stacked goods are taken away from the machine and can automatically go onto a clean goods conveyor, if available. Some machines may have a larger footprint as the takeaway conveyor is external to the machine. Depending on the equipment design, this takeaway conveyor might be in-line with the machine for a narrow footprint, or extend out either side, increasing base machine width. Items must be sorted by type prior to being fed into this machine. Sorting can occur before or after the wash/dry process.

Sorting machines allow for all parts, regardless of size, to be processed concurrently. The process of measuring for size may have a detrimental effect on operator throughput because the machine may need extra time to measure each individual part, or delay infeed of the next item fed if it’s a different size. This sorting function will vary depending on how the machine is designed to operate.

The most common types of folders on the market make folds using compressed air, mechanical fold blades, and reversing conveyors. Most folders use 2 or more of these functions to make the complete fold.

Compressed air folders use compressed air to complete the primary and cross folds. The compressed air is blasted at the dry fold items. The item is either stationary or traveling along a guide while the activated air folds the part along that guide. This type of folder requires a high consumption of compressed air. This type of fold is dependent on air quality. There may be a decrease in fold quality if the supply of compressed air falls short of the manufacturer’s recommended pressure. If air filtering is poor and there is water or debris in the compressed air supply, it will limit the repeatability of the fold process.

Folders with mechanical blades are often used to complete the primary and cross folds. These mechanical components are clean, provide positive fold point of contact and need regular attention during equipment maintenance to reduce potential downtime. Folding blades often result in crisper folds of the final package when compared to compressed air folds.

Folders with multiple reverse conveyors use several variable frequency drives to reverse the conveyor drives at a specific time to complete the folds. The item traveling into a gap between two conveyors results in a cross fold when the lead-in conveyor is reversed. The complexity of these systems may present some challenges in troubleshooting the electrical system due to the increased number of drives and motors required.

Small Piece Folding Performance Metrics

All dry folding machines available on the market are directly affected by operator skill sets and the configuration of the work space. If items fed are skewed when placed by the operator on the infeed table, folds in the finished good will be skewed. Also, if the operator does not allow for proper spacing between the goods or places multiple goods on the infeed table of the machine, that can cause the folds to be incorrect and possibly do damage to the folding machine. Operator skill influences all aspects of quality.

Equipment capability or throughput capacity is a relatively simple formula. Using the folding machine measured speed at the infeed table, divide by the sum of the measured piece length, plus handling time converted into distance. The example shown below is the first step in establishing production targets for equipment operators.

Example: Folding machine infeed 150 FPM, 30” long towel and 2.5 seconds handling time.

FPM x Inch/Ft = In/min, (150 x 12) = 1,800 in/min

In/min ÷ sec/min = (1,800 ÷ 60) = 30 in/sec

Machine speed in Inch/min ÷ (handling time converted to in/sec) + part length = Pieces per minute

1,800 ÷ ((2.5 x 30) + 30) = 17.14 or 17 Pieces per minute

The example above is only a sample of single item base calculation, this should be measured against an actual operator using a sample lot of 100 parts fed.

Braun’s Project Management delivers end-to-end consultative services in the design, construction, and operation of the laundry facility at the Hyatt Regency Convention Hotel in Seattle, Washington, the Pacific Northwest’s largest Hotel.

While the premier centerpiece of hospitality in Seattle, Washington was still just a vision, Braun’s Project Management Team was already hard at work providing consultative services to the owners, architects and engineers. The new construction of a 45-story mixed use high rise featuring 1,260 hotel rooms, three restaurants, 100,000 square feet of meeting and conference centers, and two ballrooms, required the laundry contractor have a commitment to sound design principles, a deep understanding of laundry processing requirements, and project management experience that only Braun is positioned to provide. From the modeling of the waste water stream, utility design, facility layout and detailed production analysis, Braun integrated with the construction team to design and build a facility that not only supports the current hotel but will also allow the work of three additional properties to be completed at the state-of-the-art laundry at the Hyatt Regency.

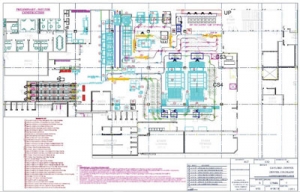

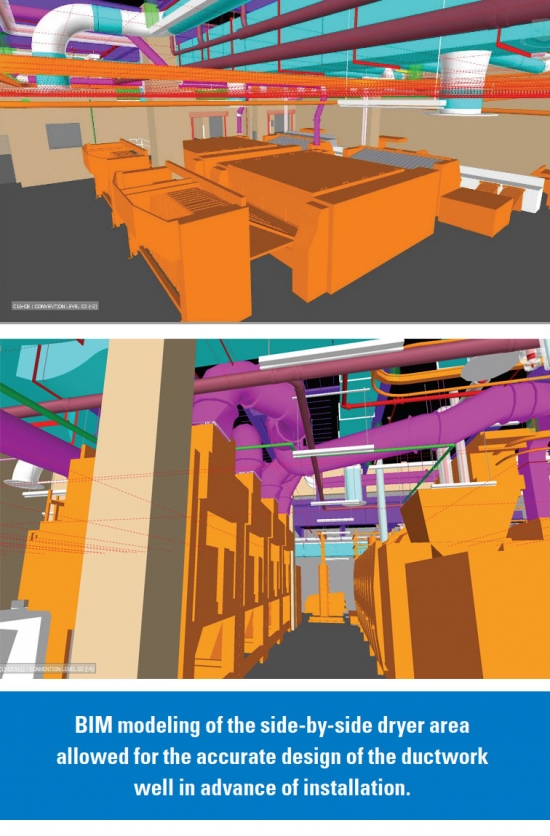

Braun’s compliment of design services allowed the laundry, material handling systems, valet and utility systems to be designed and developed through Building Information Modeling BIM). The BIM design process provided a visual build-out of the facility and accurate forecasting of materials, timing of critical path requirements, and deconfliction of adjacent design components to facilitate a flexible and cost-efficient transition from design through build. Laundry facility design continues to be driven by the capital outlay requirements, for both initial investment and working capital, necessary to achieve a desired level of production capacity and the respective return on investment of the project. This starts with integration of a capable laundry equipment provider as the management begins developing the future business requirements of the facility. Initial planning considerations and equipment capabilities can therefore be appropriately included into the capacity analysis and facility infrastructure requirements during planning. The process ends when the project is fully functional and on track, or exceeding, initial projections for production. Braun’s integrated approach to project management provides industry experience across every facet of laundry production and design. It is critical that owners and operators track performance post project implementation to assure real operating production results meet the initial projects stated objectives and therefore track towards the return on investment. Braun’s WASHNET® decision support software has the capacity to provide real time production reporting and utility monitoring to managers so they may efficiently monitor their investment and manage operations. Purely designing a facility layout no longer provides clients with a value added service and can be a hinderance to actual project development.

Braun’s integration with the Hyatt Regency’s Team provided the opportunity to install a turnkey commercial laundry solution located three floors below grade. Braun managed the complete build out of the laundry and stayed onboard to get the team off and running. Soiled linen is fed to the laundry through a common chute, available to housekeepers on all 45 stories of the hotel. The linen is received directly onto a storage conveyor system that feeds the 12-station sorting conveyor and allows manual loading of off premise goods through a cart dumper. Operators input full slings into the system which are fed according to the managers production schedule into the tunnel system. The design allows the facility to achieve industry leading pounds per operator hour through an ergonomic flow of material, a critical design requirement incorporated by Braun during initial objective identification with the owners.

Braun’s integration with the Hyatt Regency’s Team provided the opportunity to install a turnkey commercial laundry solution located three floors below grade. Braun managed the complete build out of the laundry and stayed onboard to get the team off and running. Soiled linen is fed to the laundry through a common chute, available to housekeepers on all 45 stories of the hotel. The linen is received directly onto a storage conveyor system that feeds the 12-station sorting conveyor and allows manual loading of off premise goods through a cart dumper. Operators input full slings into the system which are fed according to the managers production schedule into the tunnel system. The design allows the facility to achieve industry leading pounds per operator hour through an ergonomic flow of material, a critical design requirement incorporated by Braun during initial objective identification with the owners.

A Braun 150 Batch Tunnel Washer and Press System is complimented by three true side-by-side 300PBS System Dryers and a bypass location that feed to a common unload conveyor. The small footprint of the tunnel system maximizes productive use of the operating space and routing of the rail system allows incorporation of two standalone open pocket washers and a Braun 300PT dryer for small batch and quick turnaround linen needs. The tunnel’s single helicoid design offers a hygienic and productive solution to the properties mix of Hotel, Spa, and F&B (food & beverage) linen.

A Braun 150 Batch Tunnel Washer and Press System is complimented by three true side-by-side 300PBS System Dryers and a bypass location that feed to a common unload conveyor. The small footprint of the tunnel system maximizes productive use of the operating space and routing of the rail system allows incorporation of two standalone open pocket washers and a Braun 300PT dryer for small batch and quick turnaround linen needs. The tunnel’s single helicoid design offers a hygienic and productive solution to the properties mix of Hotel, Spa, and F&B (food & beverage) linen.

The system unloads to a clean side rail lift where goods are routed to one of two Braun Precision Series® Ironing Lines or Small Piece Folders. The ironing lines feature Braun’s Precision Series® Spreader Feeder and provide dual sorting of finished goods before discharging onto a common finished goods takeaway conveyor. The single point pack out is collocated to the finished goods storage area and hospitality elevators for low par requirements and efficient flow of material through the laundry.

Braun’s customer and processing focused approach to Project Management allowed the team to design and develop a complex laundry solution to service three restaurants, a combination of over 2,000 hotel rooms, multiple spas and a convention space in under 9,300 Square Feet. Braun’s focus on design and analytics provides its customers with best-in-class management of the process through partnership with clients from the start. The laundry team now utilizes integrated systems reporting to manage the facility and is meeting production targets to realize their return on investment.

Braun’s customer and processing focused approach to Project Management allowed the team to design and develop a complex laundry solution to service three restaurants, a combination of over 2,000 hotel rooms, multiple spas and a convention space in under 9,300 Square Feet. Braun’s focus on design and analytics provides its customers with best-in-class management of the process through partnership with clients from the start. The laundry team now utilizes integrated systems reporting to manage the facility and is meeting production targets to realize their return on investment.

– D. Palmer

The December 2018 opening of the Gaylord Rockies Resort and Convention Center was an exciting time for the Aurora, CO community. However, before ground was ever broken, years of planning were undertaken for this $800 Million project.

G.A. Braun, Inc. first became involved in the project in early 2015, closely working with General Construction Firms, Engineers, and Architects on the requirements needed for a laundry facility to support a resort that would feature more than 1,500 rooms, 4 restaurants, a convention center, and indoor and outdoor pools. As with most projects of this scale, there were many changes and revisions to the design, and Braun was able to answer the call at every turn.

After working on the design up front, Braun was awarded the contract for the entire laundry facility. This included a soiled sort monorail system, a clean side monorail system, a multi-conveyor uniform distribution system, valet equipment, a compressed air system – everything down to the trench covers and water fountains. “Not only was Braun an integral part of the planning process, they also took part in the competitive bidding process to Mortenson/Welbro during the buy-out phase of the project with the owner. Braun provided competitive costs that aligned with the laundry plan and helped value engineer the laundry to a budget that was acceptable to the owner” says Michael C. Renella, the Senior Project Manager with Mortenson/Welbro, who were responsible for construction.

After working on the design up front, Braun was awarded the contract for the entire laundry facility. This included a soiled sort monorail system, a clean side monorail system, a multi-conveyor uniform distribution system, valet equipment, a compressed air system – everything down to the trench covers and water fountains. “Not only was Braun an integral part of the planning process, they also took part in the competitive bidding process to Mortenson/Welbro during the buy-out phase of the project with the owner. Braun provided competitive costs that aligned with the laundry plan and helped value engineer the laundry to a budget that was acceptable to the owner” says Michael C. Renella, the Senior Project Manager with Mortenson/Welbro, who were responsible for construction.

Over the coming months, Braun’s Project Management Department worked with the engineering teams at the site to finalize the design. Given that the laundry facility was sharing space on the first floor of the two-story Convention Center, any available space was at a premium, and any errors could have major impacts on the overall convention center project. Utilizing Building Information Modeling (BIM), Braun was able to provide a three-dimensional computer simulation of the exact layout of the laundry. Integrating with the design team, this allowed for all utility routing to be accurately designed ahead of time, as well as prevent any conflicts in the design.

Braun continued to work closely with the construction team throughout the next phases of the project. For Braun, this was equipment installation. Careful coordination was also required for this phase, as the rigging of Braun’s Batch Tunnel Washer was required to occur prior to the construction of a particular wall in the convention center. Braun’s Project Management team planned and executed this complex rig without issue and completed the installation of all contracted equipment on time and within budget.

Over the course of the final year of the project, Braun assisted third party contractors (many of whom had never seen or worked on laundry equipment) with the remaining installation tasks by creating a detailed punch list and providing a continuously updated project timeline. Braun continued open lines of communication with the construction team, as well as the other contracted equipment providers, and maintained a coordinated, synchronized schedule. With the property having already booked 1.1 million room nights prior to opening, there could be no margin for error in the schedule. When the Convention Center was ready to obtain its Temporary Certificate of Occupancy, the Braun team was on site to facilitate the turnover to and training of the end users. “Braun worked closely with Mortenson/Welbro to establish a successful timeline of events for the laundry facility. With Braun’s assistance, our turnover of the laundry facility was a success with minimal punch list items,” says Renella. “Braun will be my first call for any future laundry needs.”

We size up the pros and cons of batch press and centrifugal extractors

No matter what tunnel washer you’re using, the downstream equipment is equally important to overall system performance. This article presents a brief, high-level overview of extraction methods. In general, there are two types of extraction equipment commonly used in batch tunnel systems. The first is a batch press extractor; the second is a centrifugal extractor.

Batch Press Extractors

Press extractors are really quite simple machines as far as the function they perform. They accept a load from the tunnel into a round basket and then squeeze water out of the goods by means of a hydraulic ram with a rubber membrane attached. However, the actual process is a bit more complex. Removing as much water as possible within the parameter of the programmed tunnel cycle time is a critical aspect of the overall system performance. The reason is that the less moisture you remove via the press means longer drying time and/or ironer slowdowns that reduce efficiency.

Press extractors are really quite simple machines as far as the function they perform. They accept a load from the tunnel into a round basket and then squeeze water out of the goods by means of a hydraulic ram with a rubber membrane attached. However, the actual process is a bit more complex. Removing as much water as possible within the parameter of the programmed tunnel cycle time is a critical aspect of the overall system performance. The reason is that the less moisture you remove via the press means longer drying time and/or ironer slowdowns that reduce efficiency.

The press cycle as noted above is governed by the overall cycle time of the tunnel. The press cycle must be programmed to be slightly shorter than the tunnel cycle so it is always ready when the tunnel cycle ends. Some manufacturers’ presses link the controls together between press and tunnel, thus allowing the press to stay in sync with the tunnel cycle. This may mean short-cycling the press to ensure that it’s ready for the incoming load. Unfortunately, many of the time functions of the press are fixed, such as lowering/raising the basket, ram up/down movement, and cake-ejection time. This typically leaves only the time under high pressure variable that can be adjusted, so shorter tunnel cycles inevitability mean less time under high pressure and thus more moisture left in the goods.

There are two ways that manufacturers try to achieve this goal of reduced cycle times without sacrificing moisture extraction: larger baskets and/or higher maximum pressure. Each method has its pros and cons. First let’s take a look at enlarging the basket diameter to reduce the height of the cake. This allows water to more easily escape during the high pressure cycle of the press. However, as the diameter becomes larger and the cake height continues to decline, this results in uneven distribution of goods as they flow into the basket, which can become a problem. Therefore most manufacturers have settled into basket diameters for presses with rated-load capacities of 150- 250 lbs. (68-113 kg) with press basket/ membrane diameters of between 39-52 inches (99-132 cm). However, as discussed above, a larger diameter isn’t the complete answer. A balance of the right basket diameter (cake height) coupled with proper formula-development creates the optimal relationship between pressure, time, material type and moisture extraction.

Increasing the maximum pressure definitely has advantages, up to a point. That point is reached when the maximum pressure at the membrane reaches between 40-45 bar. Above this pressure point, there is very little improvement in moisture removal, especially in a smaller basket diameter. Pressing laundry when confined in a basket creates an environment similar to a filter press. Water becomes trapped between the fibers and no amount of pressure within reasonable rates in a given time will increase the removal rate. Only time can allow this increase in pressure to work. The other disadvantage to running at higher maximum pressures is the increased wear and tear on the equipment and the linen.

Higher pressures also wreak havoc on different goods types, ranging from setting creases to linen damage. Using pressures exceeding 45 bar will set creases in fabrics, including terry products. Unless rinse is kept at ambient (room temperature), these creases may set permanently. The downside to holding rinse temperatures at room temperature is that using higher temperatures in the final rinse allows the fibers in the product to open up allowing for increased moisture removal. Holding rinse temperature at ambient levels isn’t the only downside of using higher pressure presses.

As textiles continue to evolve, many new blends of polyester and cotton products are entering the market. This trend is especially prevalent in higher-end hospitality products like sheets and pillow cases. When these blends and higher thread-count products are subjected to pressures greater than 25-30 bar, these products can be permanently damaged with thread breaks called “blowouts.” Since water is incompressible, the high pressure from the extraction press causes the water to push through the tiny gaps between the threads, resulting in small holes in the product. There are a number of ways to combat this phenomenon, and they all involve using less pressure or ramping up to a lower pressure setpoint very slowly. Another method is the use of tamp cycles, but this shortens the overall press time under high pressure, resulting in less moisture removal and a possible slowdown at the ironers.

Here and on the image above are examples of press extractors. In the photo above, the press is located at right, at the end of a tunnel washer. The press uses a hydraulic ram with a rubber membrane to squeeze water out of clean wet textiles after processing in the tunnel. The second photo shows a certrifugal press. It removes water from textiles by spinning the goods in a circular motion, much like the process used in conventional washing equipment.

As you can see from the discussion above, higher pressure isn’t always the answer. Operators need to factor in basket diameter, the types of goods you’re processing and formula capabilities before you make a decision solely on high pressure. Remember, high pressure isn’t necessarily the best solution!

Centrifugal Extractor

The other type of extractor is the centrifugal extractor. This type of extractor uses centrifugal force identical to a washer to remove moisture from the goods. The tunnel transfers goods into the extractor and it begins to spin, gradually ramping up to a high g-force extraction process. Much more time is needed to remove an equivalent amount of water as the press extractor, so tunnel cycles are typically programmed for longer periods or multiple centrifugal extractors are required to match the shorter tunnel cycles. The extra extractor(s), conveyance devices and additional controls all factor in to additional capital costs for this type of system. However, some types of goods cannot be extracted with the press extractor and require the use of centrifugal extractors. An example of this is the processing of walk-off mats in a tunnel in an industrial laundry. A press extractor would damage the mats, thus necessitating that the operator complete the extraction in a centrifugal extractor. Another example from the industrial laundry side could be uniforms. A press extractor could damage buttons on shirts and zippers on pants, although some can undergo processing in a press extractor at low-pressure settings. Even if a portion of your goods mix involves these types of items, there may be another solution that would allow for faster cycle times in your tunnel and the use of a press extractor.

Washer/Extractor Assist option

That option could be to use washer/extractors for the goods that can’t undergo processing in a press extractor, while running the rest of your mix in a tunnel with a press extractor. This option depends on the percentage of these types of goods in the makeup of the overall mix. It also assumes that you can process a percentage either by using existing washer/ extractors or by making a relatively small investment in new machinery. Taking these goods out of the tunnel and lowering cycle times could provide enough additional productivity to justify the added investment in washer/extractors, if the laundry doesn’t already have them in place.

There is much more science behind the press and centrifugal extractors, and we encourage readers to look more deeply into the technical details of this topic.

The city of Houston has shown incredible resiliency in the months and years following the devastation and lasting impacts of Hurricane Harvey, which struck the Texas coast in August of 2017. The city and surrounding areas have rebounded with a fervor that can only be admired. Among them, Giang Tran, owner of D2R Linens, whose business was totally destroyed, first by a fire, and finished off by Harvey.

D2R contacted G.A. Braun Inc. to assist with the reconstruction of the business. During the following months, Braun’s sales and project management personnel worked closely with D2R to completely redesign the layout of their building. This allowed for the reconstruction of the building to be based around the new laundry equipment layout.

Braun assisted D2R by providing detailed drawings of the utility connection points in the laundry to each contracted trade prior to construction. These accurate models allowed for exact material takeoffs and supported ownership’s need to keep the project on budget, as well as expedite the installation.

Instead of a large bank of small washers and dryers, which is how the laundry previously had operated, Braun provided three 600-pound Top Side Loader Washer Extractors. This product perfectly complimented the niche market that D2R Linens services, which requires smaller batch sizes. The washers are complemented by two 300-pound Pass-Through Dryers, two complete Precision Series Finishing Lines, and three Precision Series Small Piece Folders.

“In order to maximize our productivity, we partnered with G.A Braun, Inc. to provide us with the most reliable, innovative, and durable machines to date,” says Giang. “Of all the laundry equipment companies out there, we chose Braun because they possess the same family culture we do.”

Braun was present during every step of the reconstruction, including design drawings and installation criteria, on-site for pre-construction meetings, managing the contracted rigging team, equipment start-up, and training. Braun also interfaced with D2R’s retained architect and mechanical, electrical and process (MEP) Contractors.

D2R’s new laundry equipment allows them to accomplish in one shift what they had previously been processing in three. Furthermore, the 20,000 sq. ft. facility was designed with room for future equipment, allowing for greater than 60% growth. Offering their customers a variety of services, including same-day service, D2R Linen is poised for future business growth opportunities in Houston.

When Vantage Healthcare Linen, Erie, Pennsylvania realized the need to replace their 24 year old Braun batch tunnel washing system, dryers, and small piece folders, they looked no further than G. A. Braun, Inc.

Todd Lohr, Vantage Healthcare’s Director of Operations, was extremely satisfied with the production of their Braun equipment over the years, as well as his experience with Braun’s service and parts organizations. As a result of his experience with Braun, Todd quickly arranged to meet with the Braun team for consultation, and the opportunity to replace his existing equipment.

Braun’s design proposal and scope of work was developed under the requirements for retooling the existing laundry operation at Vantage Healthcare Linen and focused on a solution that maximized the use of the allocated facility space and provided the most efficient processing environment. All of this was accomplished while making certain these efficiencies were retained, and in some cases enhanced, as Vantage extended operations and looked to the long-term growth and sustainability of their business.

Braun’s design proposal and scope of work was developed under the requirements for retooling the existing laundry operation at Vantage Healthcare Linen and focused on a solution that maximized the use of the allocated facility space and provided the most efficient processing environment. All of this was accomplished while making certain these efficiencies were retained, and in some cases enhanced, as Vantage extended operations and looked to the long-term growth and sustainability of their business.

Braun’s approach to integrated project management was leveraged to maintain the project schedule in accordance with the agreed-upon objectives and set forth by Vantage Healthcare Linen. Braun coordinated the equipment delivery and freight loading plan to coincide with the rig-out of the existing equipment and the off-loading of the new equipment. Braun’s expertise in equipment rigging was key given the aggressive timeline for project execution. In addition, Braun partnered with an experienced 3rd Party MEP contractor to execute the equipment utility systems installation. The MEP Contractor was responsible for reviewing and validating the existing utility systems in the Vantage Healthcare facility to make certain all were sized accordingly to support the requirements of the new equipment. To ensure the plant did not experience lost production, work was completed during off-shift hours as well as on weekends. The Braun Project Management Team prepared and provided all the equipment specifications as well as the utility connection overlay to the MEP contractor so fabrication of raw materials to support the installation could be completed in advance to expedite the schedule. All the coordination and planning, including project meeting sessions on-site as well as via teleconference, resulted in a safe and effectively executed retool of the laundry.

The plan was continually reviewed and refined in preparation for the project execution to assure that the provided solution exceeded the level of production and quality expected by Vantage Healthcare Linen.

The plan was continually reviewed and refined in preparation for the project execution to assure that the provided solution exceeded the level of production and quality expected by Vantage Healthcare Linen.

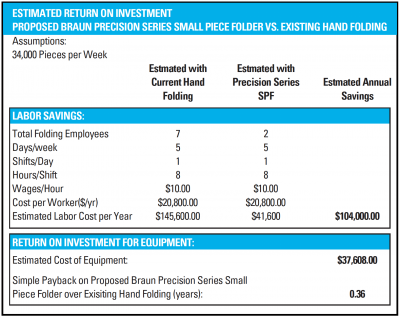

“Analytical details combined with concise presentation materials are critical so that the business owner can make important strategic decisions. Equally important was adherence to project activity timelines. This was essential to complete Vantage Healthcare’s laundry re-tool on-time and on budget. We also provided a complete ROI analysis which included savings of all utilities, parts and maintenance, labor, and a reduction in linen replacement costs”; stated Cliff Quick, Director of Inside Sales and Project Management, G. A. Braun, Inc.

The team at Braun developed a detailed project activity timeline in coordination with Vantage to determine the appropriate timing and activity for both the installation and training of the staff for all provided equipment. “The facility re-tool required minimal downtime with extremely tight schedules”; stated Quick.

With Vantage Healthcare growing, we know we made the right decision to partner with Braun.

The regional sales manager, service, and project management team are A-1”; stated Todd Lohr, Vantage Healthcare’s Director of Operations.

Braun’s equipment solution included a 130 lb. 16 chamber 130 lb. remanufactured Batch Tunnel Washing System, a 130 lb. remanufactured batch press extractor, 150 lb. dual cake elevating/nesting shuttle, 5-each new 300 lb. side-by-side gas system dryers, and 3 new Precision Series Small Piece Folders.

“The remanufactured tunnel looks and functions like new, as does the remanufactured press, and we were given a new machine warranty for both!

Our new Braun side-by-side dryers allowed us to add two additional dryers to our layout in the same footprint as the old system. This provided us with the capability to add more processing capacity without taking up more space, and the process is more efficient.

We selected Braun’s Precision Series Small Piece Folders because of their durability, speed, and ease of maintenance. Braun was able to put three machines where their competitors could only fit 2, and those were not capable of the production rates for healthcare items as the Braun machines are.”; added Lohr.

Braun’s ultimate goal is to complete value-adding projects on-time and on-budget, in line with the goals and expectations of our client partners through comprehensive analysis, consultation, design, and installation.

Keeping ironers optimized from a utilization and maintenance perspective is the best way to realize an ROI from a textile finishing line. As we review the science behind the ironing process, a simple model (Figure 1: Ironing Pie®) is used to depict the four major variables that dictate capability. This article will explain the science behind these components. Although brief, this description of the “Ironing Pie” is an important concept to understand. It is critical that laundry operators understand the relationship between each piece, so that they can properly establish formulas for processing linens in an efficient and cost-effective manner.

The four Ironing Pie components; temperature, moisture content, pressure and time are shown as equals only as a point of reference. Equal and balanced distribution of the four elements is not the case in a true ironing application.

The four Ironing Pie components; temperature, moisture content, pressure and time are shown as equals only as a point of reference. Equal and balanced distribution of the four elements is not the case in a true ironing application.

IRONING TEMPERATURE

Heat inarguably has the single-most direct impact on an ironer’s ability to press fabric. Heat as a variable must be valued as the chest surface working temperature. The most common temperature range is from 325°–365°F ([162°–185°C] ideal operating range based on the heat source and the melt points of various blended materials). The most common form of ironer heat energy is steam, given that most laundry facilities already have boilers and the capacity to support the steam demands of the ironer (it should be noted that steam boilers run more efficiently when they have the proper load placed on them). Steam ironers tend to operate in the 325°–340°F (162-171°C) range, while thermal fluid heated units can operate at higher temperatures. Variations in chest temperatures during production can result in poor ironed quality with damp/wet items exiting the ironer, while prolonged exposure to extreme high temperatures can damage items.

This magnifies the importance of having a consistent moisture content in the linens as they are presented to the finishing lines. By doing so, established formulas will provide consistent quality and production output.

When establishing formula operating temperatures, it’s recommended to consult your linen provider for guidance on how to properly care for your items. Knowing the items’ maximum recommended exposure for temperature is always an important point to consider. The most common configuration is to operate the ironer as hot as possible and adjust line speed to control an item’s exposure to heat.

Once an ironer’s maximum operating temperature is established, any reduction in chest-surface temperatures will increase the time required for the items to be under pressure, resulting in slower line speeds. To offset operating at a slower line speed, other pieces of the Ironing Pie must be addressed. You can reduce the items’ moisture content by increasing your extraction times, or extraction time under pressure (depending on how the linens are washed in conventional washer/ extractors, or if they are processed in batch tunnels). Additionally, you can positively influence line speeds to address higher moisture content by adding additional rolls/surface area to your ironer.

MATERIALS MOISTURE CONTENT

Moisture Content is a key component in the Ironing Pie. It starts as a weighted comparison of a linen’s ability to retain moisture after undergoing processing through a press or washer/extractor cycle. This is achieved by weighing dry linens before being washed and again after the linens have been processed as delivered to the finishing line ready for ironing. Moisture content can then be calculated by following the formula below:

It’s recommended that items contain 30%-40% moisture content before ironing. Adhering to this guideline will help ensure a quality ironed finish, while minimizing linen damage. It’s true that a reduction in an item’s moisture content is directly related to increased processing line speed under temperature as noted above. But fully dried items should not be processed through an ironer. Attempting to achieve lower extraction percentages might not be practical as a scale of diminishing returns will occur with no value added. Every site is different and each needs to qualify its own capabilities for this measure. When a site is having issues controlling moisture content, pre-conditioning loads in a dryer is another process that operators can consider. What’s important is to develop a process of producing repeatable moisture content for items processed on the front end of the finishing line. Items exiting the ironer should maintain 2-3% moisture content, as this will allow smooth folds and preserve the life of the fibers, while reducing the creation of lint and static electricity. Items ironed fully dry without moisture retention present are prone to fiber damage, excessive accumulation of lint and the creation of high levels of static electricity. Increased front-end item moisture content will increase the amount of time required for an item to be under pressure, resulting in slower line speeds, which decreases throughput. To offset the impact of slower line speeds, increasing chest temperature and the contact area under pressure will help restore line speed. When chest temperature is operating at the highest potential for output, preconditioning select items has the potential to reduce moisture content, inversely restoring an ironing line’s capability for throughput. It should be noted that discharging items with elevated moisture content will typically result in poor fold quality, folding equipment jams and unplanned operational downtime. Also, it can present a hygienic liability as mold can grow on damp linens that are stored or packaged for shipment to the end user.

IRONING CONTACT PRESSURE

The Ironing Pie defines pressure as the location where the padded roll applies pressure onto a sheet against a deep chest simultaneously. There are two components to pressure: The first is the surface area under pressure, which is dictated by the size of the roll utilized and the number or rolls with which the ironer is configured. The other pressure variable is the applied surface physical force between an ironer roll and its respective chest surface. The first pressure variable is established at the time of equipment purchase, often within the customer bid specification, which defines specific site-configuration factors and performance throughput. Ironer OEMs are best suited to provide guidance in sizing an ironer, since each manufacturer will understand the impact and limitation regarding the contact area under pressure and how their ironer will perform. It’s debatable whether the use of this term might have been over-marketed. Simply put, an operator should look at the size of the ironing surface as a linear value and not the accumulative total area of square inches/centimeters. It’s necessary to understand that the impact of the contact area under pressure is fixed to the number and size of rolls utilized. It is not recommended to leverage this value as the single qualifier for ironer performance, or to justify the purchase of similar-sized two- or three-roll ironers. Many additional factors require consideration (e.g., chest type, construction, design, number of rolls and size of rolls all need to be part of the selection process). Make sure to use all factored inputs to correctly define ironing needs. A good up-front purchasing decision establishes a flatwork line return on investment for years to come.

IRONING DURATION OF TIME

The Ironing Pie defines time as three different variables. The duration of time for each variable is site-specific and all are impacted by the factors identified in the Ironing Pie. They include:

- Start Up Time

- Production Time Under Pressure

- Cool Down Time

Key input factors specific to ironer time are desired operating temperature, items processed, moisture content and contact pressures.

START UP TIME is the duration of time required to raise the temperature of the ironer from its current static or ambient temperature up to “hot” wax-ready operating temperature. This segment of time is directly dependent on the type of ironer, specifically its heat source with respect to starting chest temperatures. During this time most laundries will execute a wax procedure and will replace any missing guide ribbons so that when complete, the ironer is production ready.

PRODUCTION TIME UNDER PRESSURE is the segment of time when the ironer is hot at operational temperature and available to run flatwork production. This is when equipment utilization becomes a measurable, and where an ROI can be verified while looking for opportunities for improvement. A good approach is to tune the ironer line speed for sustainable site operations that is item-specific for predictable, repeatable results. During the utilization review, note all identified shortcomings. Some can be resolved as tuning opportunities, while others may be fixed constraints requiring a more complex series of solutions. A good objective should be to keep the ironer chest covered with items and processing with minimal gaps. Items should exit the ironer with 2%-3% moisture retention to prevent static electricity, producing a quality ironed, wrinkle-free appearance. Avoid attempting to configure line speeds to operate beyond the slowest piece of equipment or at full boiler capacity. Some cushion is required to absorb momentary changes in the plant- operating environment. Time under pressure is the amount of time that the ironer roll is pressing items into a hot chest. This value has a direct relationship to the amount of fixed contact area under pressure. The longer this linear contact pressure distance is, the less time under pressure is required to iron. Other factors that can impact time under pressure are fabrics. For example, 100% cotton will require more time under pressure than a cotton/poly blend or microfiber.

COOL DOWN TIME is the time period to lower the temperature of the ironer from operating speeds down to cooler “touch- safe” temperatures. It’s obvious that cool down times will be affected by operating temperature and the type of medium used to heat the ironer, as well as the size of the ironer itself. Even if your daily operations never fully shut down laundry boilers, it’s important to qualify the time required to cool the system for servicing the unit and restarting. Certain preventive maintenance (PM) and servicing activities should not be attempted on a hot ironer (e.g., replacing spring press, padding rolls, servicing traps/gaskets/ flanges).

The science of ironing has changed very little over the years. Rather, it is the application of technology, equipment de- signs, the heat sources used and configurations of deep chest ironers that have evolved to support the demands of the market/industry. In today’s modern laundries, the capability of the ironer is typically what dictates the production capacity of the processing line.

AUTHOR’S NOTE: “Ironing Pie®” is a registered trademark of G.A. Braun Inc

Reducing Downtime in Industrial Laundries: The Power of Proactive Maintenance

Minimizing equipment downtime is essential for maximizing productivity and extending the life of your industrial laundry equipment. A well-executed proactive maintenance (PM) program is the most effective way to prevent unexpected breakdowns, reduce repair costs, and support long-term operational efficiency.

What Makes a Strong Proactive Maintenance Plan?

An effective PM program should be tailored to your facility’s unique operational needs and include the following elements:

- Skilled employee training and onboarding

- Clear site housekeeping procedures

- Engineering team training and documentation

- Task-based risk assessments

- Access to external support resources

- Verified local contractor and OEM contacts

- Comprehensive preventive maintenance schedules

- Operational cost and trend tracking tools

- Contingency plans for operational disruptions

The Role of Engineering in Reducing Downtime

A successful PM strategy starts with the chief engineer, who defines the long-term maintenance plan, sets the budget, and ensures resources are aligned. Plant engineers manage the day-to-day execution, coordinating closely with production teams to support equipment health and minimize downtime.

Even with proactive plans in place, equipment issues can still arise. That’s why it’s critical to have a well-documented contingency plan and reliable service contacts on hand—whether for in-house fixes or external repair support.

Building an Equipment Wellness Program

Modern wellness programs use maintenance software to streamline PM tracking and automate work order management. These systems evolve with the needs of the facility and centralize all maintenance data in one easy-to-access location.

Key elements of a wellness program include:

- OEM maintenance manuals outlining service intervals and components

- On-site inventory of essential spare parts for quick repairs

- Daily, weekly, and monthly PM schedules

- Hours-of-operation-based service milestones

If you’re unsure of what parts to keep on hand, most manufacturers can provide a recommended spare parts list tailored to your equipment.

Technology and Diagnostics Improve Equipment Longevity

Today’s commercial laundry machines are equipped with advanced touchscreen controls and intuitive diagnostic tools. These platforms (PLC or PC-based) simplify troubleshooting and provide clear performance insights—eliminating guesswork and enhancing operator confidence.

Many OEMs also offer remote diagnostics, wellness contracts, and technical support services to help supplement your internal maintenance team and reduce long-term costs.

Benefits of a Proactive Maintenance and Wellness Program

- Extended machine life

- Reduced unplanned downtime

- Improved system diagnostics and planning

- Consistent software updates and control upgrades

- Better team skill development and retraining opportunities

By identifying small issues early, a PM program prevents minor problems from turning into major, costly failures.

Operator Training: The Foundation of Equipment Reliability

Proactive maintenance is most effective when paired with comprehensive training. Initial and ongoing training sessions help operators, engineers, and supervisors:

- Understand machine functionality

- Master control interfaces and diagnostic tools

- Improve productivity through proper machine usage

Training also strengthens the relationship between the laundry facility and the equipment manufacturer, ensuring continued support and education.

Final Thoughts: Be Proactive, Not Reactive

Investing in proactive maintenance and training reduces long-term costs, protects equipment, and ensures consistent production. Whether you’re maintaining current operations or preparing for future growth, a robust wellness and PM plan is key to reducing downtime and maximizing ROI.

Looking to optimize your facility’s maintenance strategy? Contact GA Braun for expert guidance, wellness programs, and service support tailored to your laundry operation.

(l/r) Metro Laundry’s Chief Engineer Mark Proctor; COO Steven Young; and Plant Manager David Slawson stand by the plant’s upgraded sheet feeder.

Hospitality laundry operators have struggled since the COVID-19 pandemic hit in March and slowed hotel bookings to a crawl. But many have seized the opportunity of a slowdown to prepare for a time when their prospects improve. Metro Laundry Service, a Washington, DC-area hotel launderer, recently collaborated with G.A. Braun Inc. on an upgrade of three sheet feeders aimed at doing just that.

Before COVID-19, Metro Laundry was growing rapidly. A second, 52,000-square-foot plant opened in 2018 with great fanfare as the business expanded. When the pandemic hit, business plummeted by as much as 95%, said COO Steven Young. The second plant, dubbed “MLS 2” was shuttered by early April. Operations were consolidated at the company’s original 24,000-square-foot plant in Capitol Heights. Among other down-time projects, discus-sions among the Metro managers and its executive team centered on making improvements to three Braun sheet feeders. The supplier company, based in Syracuse, NY, seized the opportunity to fine-tune its equipment. During the week of Sept. 28, it installed a newly upgraded feeder to replace one that Metro had. Young and his team are delighted with the revamped feeder and look for-ward to having the same upgrades applied to two other feeders. “Braun is a very valued partner of ours,” Young said. “They were part of the opening of that MLS 2 plant, and they wanted to be a part of helping MLS survive COVID and revitalizing the original plant. We’re very thankful to them for that.”

Mark Kirby, Braun’s director of finishing equipment technology, returned the compliment, thanking Metro for its collaborative input as a win-win for the company and its supplier. “Braun partnered with Metro Laundry to help define action items during the planning and development of Braun’s next generation of the Precision Series® Spreader/Feeder,” Kirby said. “Feedback and observations from Metro were well received by our engineering team. This collaboration produced positive results for all involved in the spreader/feeder upgrade.”

Braun’s team of engineers arrived at Metro on Sept. 27 to install the new feeder. The upgraded machine includes fault detection and the company’s patented spread-detection device, re-engineered spread clamps and more.

The Braun tech experts stayed at Metro through Sept. 30. Young said his team was pleased to have them explain the up-graded machine and provide on-site training in other areas. This was particularly helpful because as part of the consolidation of the two plants, older equipment at MLS 1 was phased out in favor of newer equipment moved from MLS 2, Young said. Most of the executive and engineering staff at MLS 1 had limited knowledge of the equipment from the other plant. The feeder installation gave them an opportunity to learn. “During that time that they were here, a stretch of about four days, was an opportunity for our maintenance and mechanics and engineering teams to pick their brains and learn as much about the equipment as possible,” Young said. Now as hotel business begins to pick up, fueled by Washington, DC-area events such as the recent Prayer and Black Lives Matter marches, Young is feeling optimistic that Metro will weather the storm of COVID-19 with a revitalized plant and staff. “We took this situation and tried to turn a negative into a positive and say, ‘Hey, let’s just use this as an opportunity to revitalize the plant,’” he said. “Revitalize it from an equipment standpoint and from a staffing standpoint.

Now we have more maintenance coverage and management than we had before, which has taken some pressure off all of us, so to speak. It allows us to operate better. There’s still a lot of challenges. We’re adjusting as we go along.”

‘YOU’VE GOT TO BE INNOVATIVE’— Q&A with J.B. WERNER

G.A. Braun CEO describes coping with COVID, recruitment/retention challenges and more

By Jack Morgan

In recognition of the 75th anniversary of G.A. Braun Inc., Syracuse, NY, Textile Services recently clicked into a Zoom interview with J.B. Werner, Braun CEO and board chairman. Our discussion ranged over the impact of COVID-19, market trends, regulatory hurdles, overseas expansion and more. Excerpts—edited and condensed for clarity—follow.

Fourth-generation CEO J.B. Werner, photographed in his office at the G.A. Braun manufacturing plant in Syracuse, NY., is enjoying the company’s 75th anniversary. Innovation is the key to its future, he says.

We hear that a lot of your customer base have deferred on machinery purchases or any capital expenditures due to the uncertainty of the pandemic. With various states opening up, is that likely to change in the second half of ’21?

We’re going to see some pickup on the uniform side, but they’re almost back to where they were pre-COVID. The hospital side’s still down but improving. Obviously, the linen in hospitality is down. I think we’ll see a pickup in hospitality, but more toward the resorts because people can’t wait to go out on vacation. The hotels that cater to business travelers, I think that’s going to go down. Businesses are going to do more Zoom meetings and not traveling as much compared to pre-Covid levels.

Any improvements planned for your manufacturing facility?

We opened the first building 2009 and then we put in the addition and doubled it in 2015. We’ve continued to invest in capital equipment in the factory for fabrication and those types of things. We could expand if we wanted to. We’ve got land to do that. We have no plans to do so at this time.

With no Clean Show this year, how have you changed your approach to marketing your equipment and systems?

It gives us an opportunity. Every two years it’s difficult to come up with new equipment…We’ve got a lot of new product development going on, which if we had the show this year, we wouldn’t be able to show as many new products. By the next clean show, we’ll have a number of new products that we will showcase.

You’ve said people at Braun are happy to be working there. Has that made recruitment/retention better? Have you seen less turnover, or is it any easier when you need to hire an engineer?

At times recruitment can be challenging but we are active with local vocational schools and universities in the area. We provide tours, explain what we do and provide an overview of the industry. We’ve found this approach to be extremely beneficial.

Are you sending sales reps out? I’ve heard with some companies, it’s all phone or “Zoom calls.”

Yes, our sales representatives are all traveling. No question.

How about your pursuit of overseas markets? Has that been affected by COVID particularly?

Yes. Especially the Far East. I think they’re still pretty closed down. We’re seeing some activity in Korea. Central and South America, and we continue to be very active in those areas.

How about supply chain? Have you had issues getting parts?

No. Because all of our suppliers are U.S. based it was rare if we ran into an issue and have had little disruption.

Your factory is ISO certified. Does that give your sales reps any competitive advantage when they’re pitching your equipment?

- Definitely, ISO practices contribute to making the development, manufacturing, and supply of products and services more efficient and safe. I’m not sure who is even ISO certified here in the states. I don’t think there are any ISO-certified laundry equipment manufacturers.

When you do your proposals, do they put that into the proposal? Do they ask about ISO certification when you’re bidding it now?

Some do. More of the government RFPs (request for proposals) will have that.

Is government contracting a significant part of your business?

We do a lot of VA (Veterans Administration) business. We always have. That’s always been a strong point of our company. Yes. A lot of the RFPs have what’s called a “Made in America” clause, not all of them, but many do. With the current administration’s push to “Buy American” I believe we will see more of this.

How do you feel about making it to 75 years in this highly competitive business?

We’re very excited about it. We’re very proud to have 75 years in this business. There are not many companies that can say that. Having four generations basically, if you start back from the Prosperity Company, the chemical company (see related story on pg. 40), I’m the fourth generation in the laundry business. The third generation in the company for Braun.

Looking past COVID, what would you say is the biggest challenge that Braun is facing in the next 15-20 years?

You’ve got to be innovative. You got to keep coming up with new products. If you don’t, the market will pass you by. That’s where we focus. Every year, we get together, gather industry input as to what needs are out there and what they would like to see. Then we talk about different products that we should consider building, and make plans accordingly, depending on which ones we decide we’re going to go ahead with. We’ve several brand-new products coming out between now and the Clean Show (July 30-Aug. 2, 2022, Atlanta) and we are looking forward to showcasing them.