Scheduled Maintenance

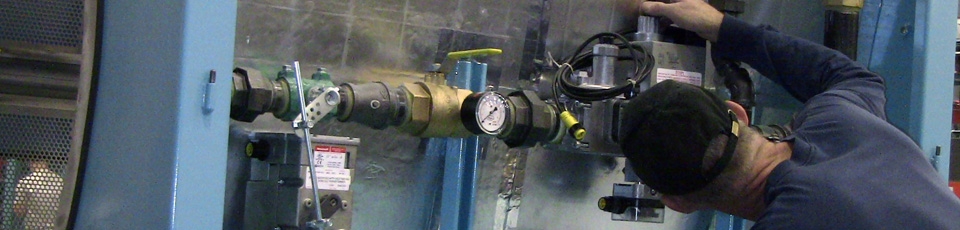

Shifting from reactive to scheduled maintenance is essential for maintaining reliable, durable equipment and processes. Braun works with you to develop a Scheduled Maintenance Program tailored to extend the life of your equipment and minimize unplanned maintenance.

Program Highlights:

- Proactive Approach: Includes lubricating, adjusting, and replacing minor components to ensure equipment longevity.

- Comprehensive Care: Features non-destructive testing, periodic inspections, and pre-planned maintenance procedures to address issues identified during testing and inspections.

Benefits of Implementing a Scheduled Maintenance Program:

- Asset Value Preservation

- Improved Energy Efficiency

- Enhanced Safety and Quality Conditions

- Increased Capacity and Throughput

- Reduced Equipment Downtime

- Ongoing Training for Your Operations Team

Contact Information:

For more information about our Scheduled Maintenance Programs, please contact our Field Service Coordinator at (800) 432-7286 x 237.

Explore Our Services

Ready to get started? Let’s talk today.

Our Products

Need Parts?

We can help you find the exact part you need.

Looking for Financing?

We have a variety of financing options available.

Want to see our equipment?

View our digital catalog site.

Looking for remanufactured equipment?

Learn about our pre-owned equipment, remanufactured by Braun!