Navigating Industrial Dryer Emissions Compliance in California and Beyond

Tighter Air Emission Standards Are Changing How Industrial Laundries Operate

California continues to lead the nation in environmental regulations, including some of the strictest air emission standards for industrial equipment. While most headlines focus on vehicle emissions, industrial laundry operators—particularly those in Southern California—face growing scrutiny around dryer air emissions, especially NOx (nitrogen oxides) and CO (carbon monoxide) levels.

If you’re an operator looking to replace older dryers with more efficient and compliant models, understanding the latest regulations is critical to making an informed investment and avoiding costly non-compliance issues.

What Operators Need to Know About SCAQMD Rule 1147

The South Coast Air Quality Management District (SCAQMD) enforces Rule 1147, which governs NOx and CO emissions for industrial dryers in Southern California. Under this rule:

- Dryers must emit no more than 30 ppm NOx and 400 ppm CO.

- Equipment with a heat input of less than 2 million BTU/hr, burning only natural gas and processing non-VOC products, may be exempt from air permitting.

Even if you’re not based in California, similar air quality standards are emerging in other states, making this information relevant across the U.S.

How to Choose a Compliant Industrial Dryer

When investing in a new industrial dryer, you must evaluate both performance and regulatory compliance. Here are critical questions to ask your OEM or equipment supplier:

1. Does the Dryer Qualify for an Emissions Exemption?

If your laundry does not process VOC-laden items (like shop towels or bar towels), and your dryer is under the 2 million BTU/hr threshold, it may qualify for an exemption. Ask your manufacturer:

- What is the dryer’s BTU/hr output?

- Can it be detuned to operate below 2 million BTU/hr and labeled accordingly?

- How will detuning affect efficiency and turn times?

Detuning the gas train may impact energy consumption and production rates, so it’s essential to understand these trade-offs.

2. Is the Dryer Truly Low NOx Certified?

If your operation processes VOCs or the dryer exceeds 2 million BTU/hr, you’ll need equipment that complies with Rule 1147 limits.

Don’t rely on marketing claims. Ask your vendor to provide:

- A certification letter guaranteeing compliance with 30 ppm NOx and 400 ppm CO.

- Third-party emissions test results or performance data.

Without this certification, you risk investing in equipment that may not meet local emissions standards—leading to operational delays, fines, or forced modifications.

The Importance of Preventative Maintenance for Emissions Compliance

Once your dryers are installed, compliance doesn’t stop. Most manufacturers only certify emissions during the warranty period and only if the equipment is maintained according to their guidelines.

Key maintenance practices include:

- Daily cleaning of combustion air filters

- Monitoring gas pressure and air-to-fuel ratios

- Routine inspections as outlined in the equipment manual

Failing to maintain the dryer may cause emissions to exceed permitted levels, leading to loss of efficiency and possible re-certification costs.

Avoiding Non-Compliance and Maximizing ROI

Industrial dryers are a major capital investment, and failure to meet emissions requirements can significantly increase your costs. Here’s how to protect your investment:

Do your homework on current and future local regulations

Ask OEMs the right questions before buying

Get written certifications for emissions compliance

Schedule regular maintenance to maintain certified performance

Stay updated on changes to SCAQMD Rule 1147 and similar regulations in your region

Industrial Laundry Emissions Compliance: What’s Next?

As air quality standards continue to evolve, laundry operators across the U.S. must prepare to meet stricter emissions rules—whether you’re in California, Texas, New York, or anywhere in between. By working closely with your OEM and staying informed, you can ensure your dryers are efficient, compliant, and future-proof.

Ready to Upgrade Your Dryers?

Braun offers industrial dryers engineered for low NOx performance and compliance with SCAQMD Rule 1147. Contact us today to learn more or request emissions certifications.

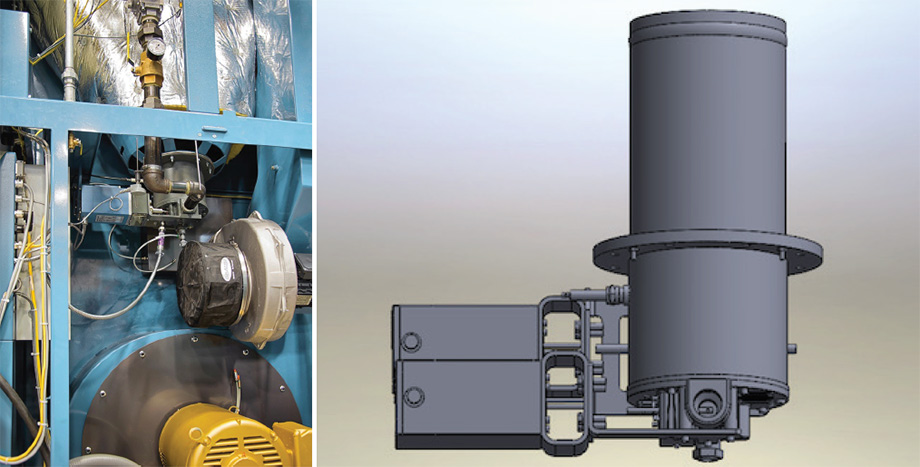

ABOVE: (l/r) Here is a view of a low NOx burner in a dryer; a graphic image of a low NOx burner; on the opening page, there is a group of three low NOx dryers in operation in a plant.